Thermodynamic

Steam Traps

Steam traps are vital components in any industrial steam system. Their main job is to efficiently remove condensate (water) and air from steam lines, without letting valuable steam escape. This helps keep equipment running smoothly, improves energy efficiency, and ensures safety throughout the entire process.

When steam is used to heat or power machinery, it cools down and turns back into water. If this water isn’t removed quickly, it can reduce the effectiveness of your equipment and even cause damage over time. Steam traps solve this problem by automatically separating the water from the steam. This keeps your system working at its best and protects your investment.

There are different types of steam traps, each designed for specific pressures, temperatures, and applications. Whether you’re managing a large boiler, a heat exchanger, or a small process line, choosing the right steam trap can make a big difference in performance and cost savings.

Steam traps are built to be dependable and durable, handling the tough conditions often found in industrial environments. They’re easy to install and maintain, making them a practical choice for busy facilities. With the right steam trap, you’ll maximize energy savings, extend the life of your equipment, and keep your operations running safely and efficiently.

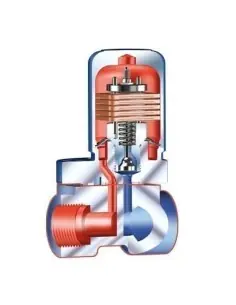

Thermostatic (Capsule)

Capsule steam trap - CONA M | ARI

Thermostatic (Bimetallic)

Bimetallic steam trap - CONA B | ARI

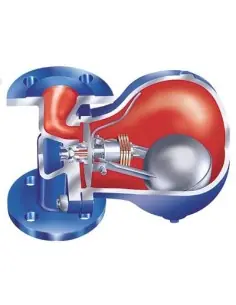

Ball Float and Thermostatic

Float & thermostatic steam trap - CONA SC / SC Plus | ARI

Ball Float and Thermostatic

Float & thermostatic steam trap - CONA S | ARI

Connectors

CONA connector | ARI

Thermostatic (Bimetallic)

CONA All-in-one | ARI

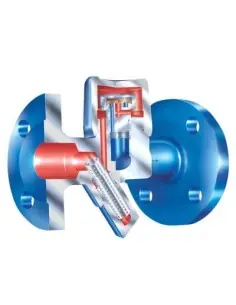

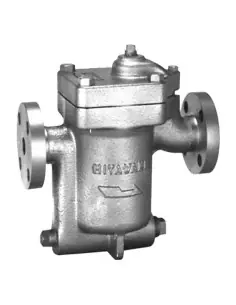

Inverted Bucket

Inverted bucket steam trap - ES5 | Miyawaki

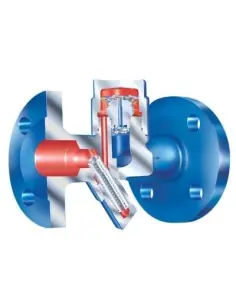

Inverted Bucket

Inverted bucket steam trap - ESU5 | Miyawaki

Inverted Bucket

Inverted bucket steam trap - ES8N | Miyawaki

Inverted Bucket

Inverted bucket steam trap - ES10 | Miyawaki

Inverted Bucket