Advanced Performance and Reliability: Inverted bucket steam trap - ES10 | Miyawaki

The Inverted bucket steam trap - ES10 | Miyawaki is your trusted solution for efficient steam system management in industrial environments. Built with durability and precision in mind, this steam trap is engineered to keep your operations running smoothly while saving energy and reducing maintenance hassles.

Features & Benefits of Inverted bucket steam trap - ES10 | Miyawaki

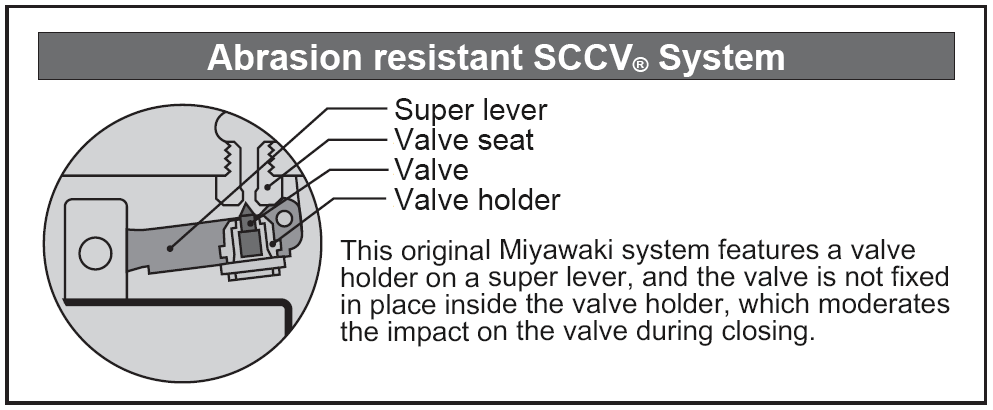

- Reliable Steam Discharge: The inverted bucket design ensures only condensate and air are discharged, keeping valuable steam inside your system and maximizing efficiency.

- Robust Construction: Made from high-quality materials, the ES10 stands up to demanding industrial use, resisting corrosion and ensuring long service life.

- Easy Maintenance: Simple internal components mean minimal downtime for cleaning or repairs, keeping your process moving at all times.

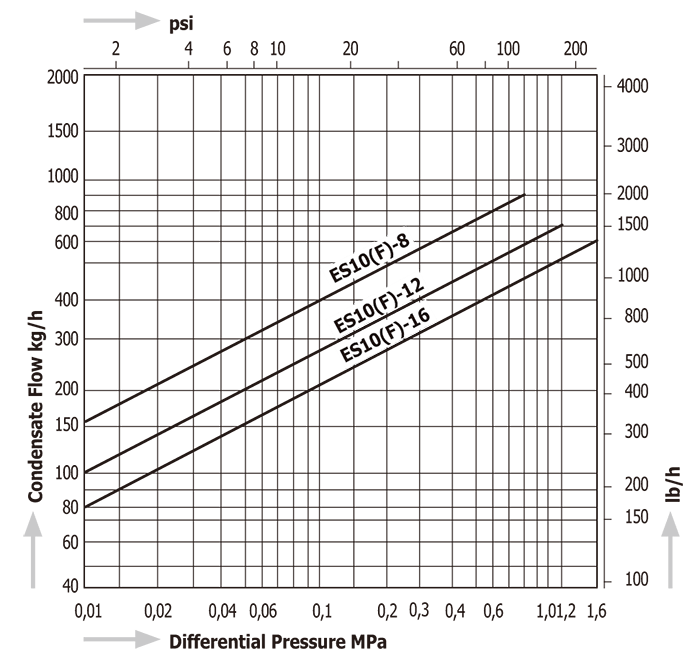

- Energy Efficient: By preventing steam loss, this steam trap helps lower energy costs and improves overall system performance.

- Versatility: Suitable for a wide range of applications such as process lines, heating systems, and more—making it a smart investment for any facility.

- Automatic Operation: The ES10 functions automatically, requiring no manual adjustments, so you can trust in consistent operation around the clock.

Experience true reliability with the Inverted bucket steam trap - ES10 | Miyawaki. Its advanced mechanism quickly reacts to changes in steam and condensate levels, delivering top-notch performance without constant supervision. The straightforward installation and user-friendly design mean even newcomers can get up and running with ease.

Boost productivity and enjoy peace of mind knowing leaks and energy loss are under control. For anyone looking for an easy-to-use yet highly effective steam trap, the ES10 is the go-to choice for safe and sustainable industrial operation.