Reliable Performance Redefined: Inverted bucket steam trap - ES5 | Miyawaki

Discover the efficiency and reliability of the Inverted bucket steam trap - ES5 | Miyawaki, a robust solution built for precision in industrial steam systems. Designed to handle demanding environments, this steam trap ensures optimal energy usage and keeps your processes running smoothly.

Features & Benefits of Inverted bucket steam trap - ES5 | Miyawaki

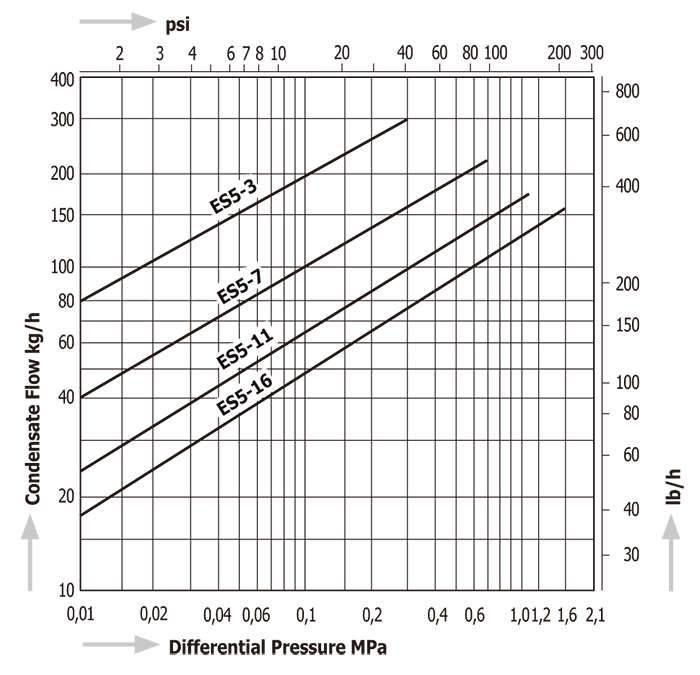

- Efficient Steam Management: Smartly removes condensate while preventing valuable steam losses. This means you get maximum use from your steam without unnecessary waste or energy costs.

- Strong and Durable Design: Made from high-quality materials, the ES5 is built to last even in tough conditions. Its rugged construction minimizes the need for replacement or frequent repairs.

- Automatic Operation: The inverted bucket mechanism works on its own, automatically opening and closing to discharge condensate. No manual intervention is needed, reducing the risk of mistakes and maintenance time.

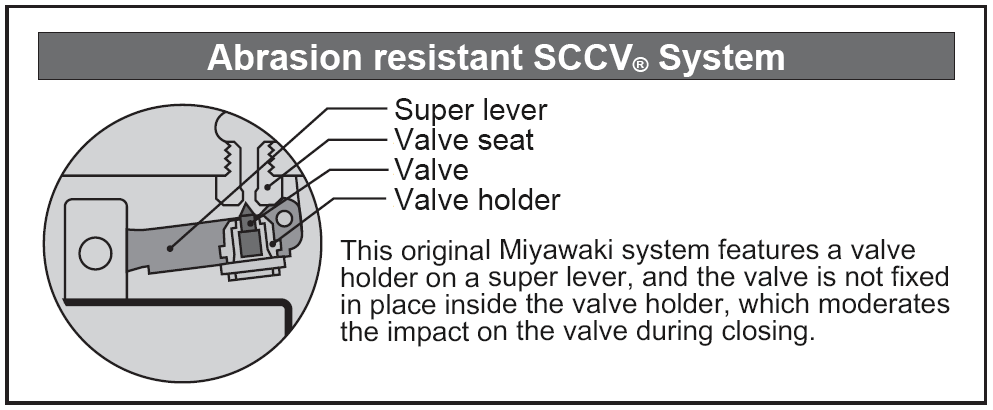

- Resistant to Dirt and Corrosion: Equipped with a large seat and a special design, the ES5 resists dirt build-up and internal corrosion, ensuring smooth operation over time.

- Energy Savings: By reducing steam leakage and efficiently removing condensate, this steam trap helps lower your plant's energy bills.

- Easy to Inspect and Maintain: The ES5 features a simple construction, making it quick to check, clean, and maintain, minimizing downtime for your operations.

- Safe and Reliable: Engineered for safety, this steam trap supports a secure workplace, reducing the risks connected with failed or faulty traps.

The Inverted bucket steam trap - ES5 | Miyawaki stands out for its practical and straightforward operation. It automatically adapts to changing steam conditions, handling varying loads without losing efficiency. Thanks to its advanced inverted bucket mechanism, you benefit from consistent performance, fewer breakdowns, and lower operating costs.

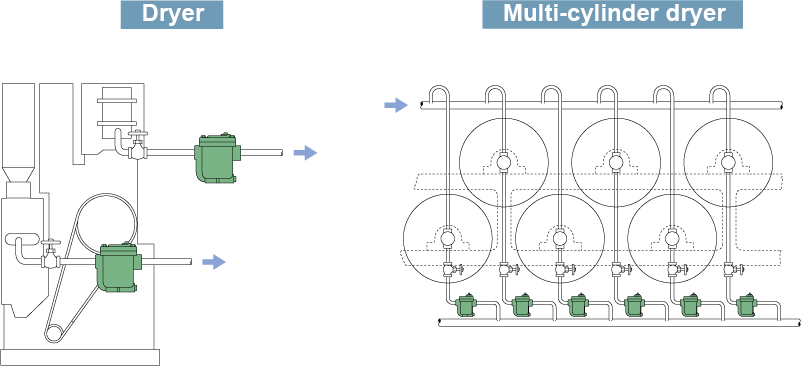

Ideal for all industrial users, the ES5 is suitable for a variety of applications, from heat exchangers to process equipment, ensuring reliable removal of condensate and air while keeping vital steam in the system. Upgrade your steam management with the ES5 and experience a difference in productivity and savings.