Reliable Performance Unlocked: Features & Benefits of the Inverted bucket steam trap - ES12N | Miyawaki

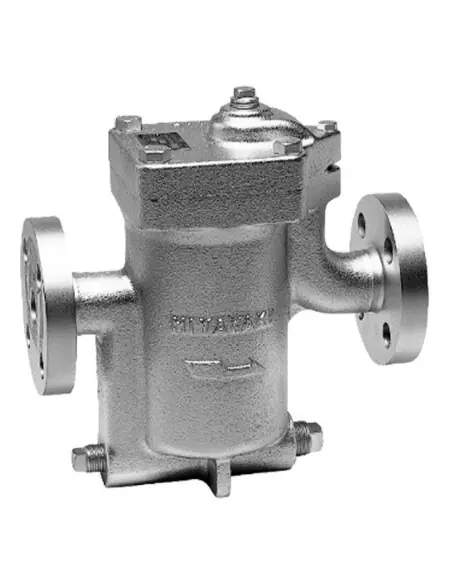

The Inverted bucket steam trap - ES12N | Miyawaki is designed for dependable steam management in industrial environments. Built for efficient operation, this steam trap ensures your systems run smoothly while minimizing maintenance. Enjoy continuous productivity with technology that stands out for its robustness and user-focused features.

This advanced steam trap uses the inverted bucket principle, making it exceptionally reliable at automatically removing condensate from steam lines. Its clever design prevents steam leaks and stops energy waste, helping you save on operational costs while safeguarding your equipment from water hammer and corrosion.

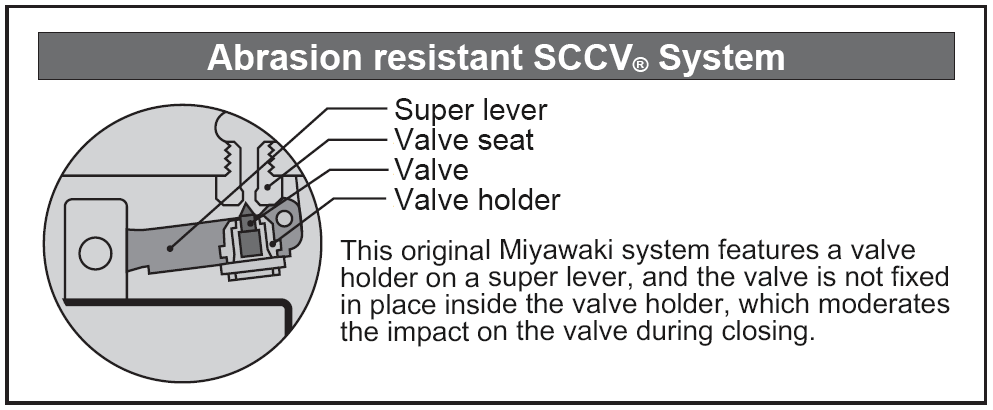

- Durable Construction: Crafted with high-quality materials, the ES12N resists corrosion and wear, making it ideal for tough industrial conditions. Its sturdy build means long service life, even under high-pressure applications.

- Efficient Condensate Removal: By effectively separating steam from condensate, your system benefits from dry steam, which improves efficiency and extends the life of your machinery.

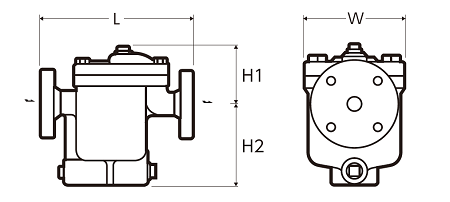

- Easy Maintenance: Simple installation and a straightforward mechanism mean less downtime. The ES12N is designed for hassle-free inspections and part replacements, keeping your workflow uninterrupted.

- Consistent Operation: The inverted bucket mechanism consistently opens and closes, adjusting to variable loads and ensuring that steam is not wasted. This translates to reliable energy savings each day.

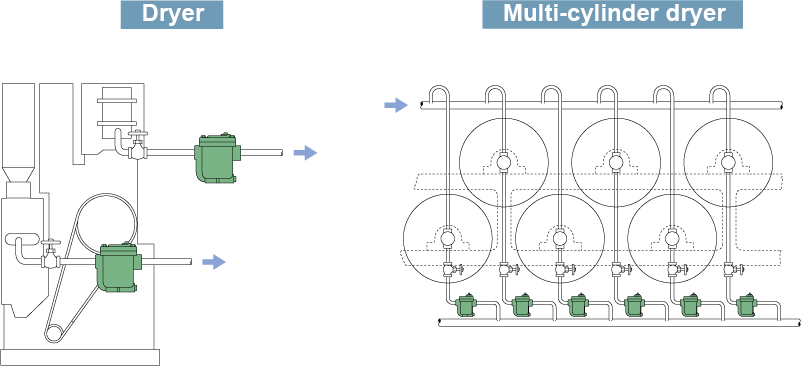

- Versatile Application: Suitable for many industrial uses, from heating to processing, this steam trap fits seamlessly into different systems, offering flexibility and peace of mind.

With the Inverted bucket steam trap - ES12N | Miyawaki, expect premium performance and lasting value. Its advanced features mean your operations are protected, your energy costs are lower, and your staff can focus on productivity rather than constant repairs. Elevate your industrial steam management with a solution built to perform and last.