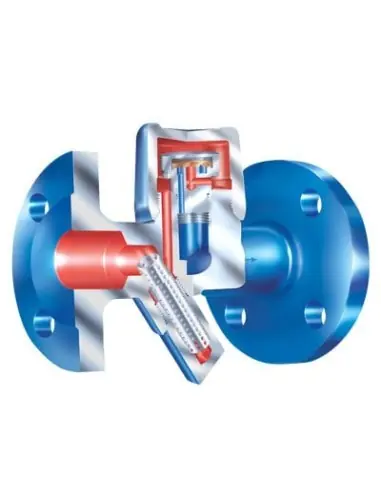

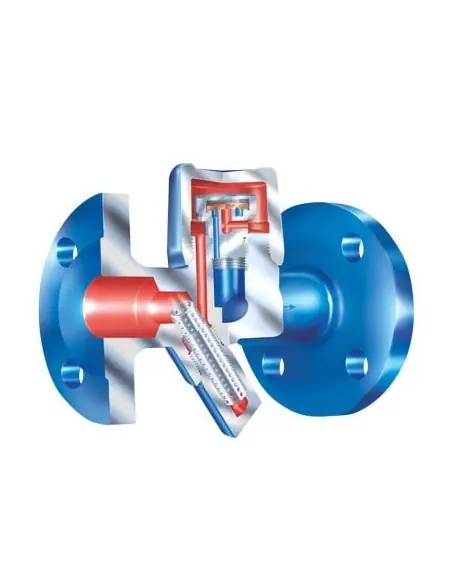

CONA® TD Thermodynamic Steam Trap Features:

- Thermodynamic Steam Trap: Designed for discharging slightly to highly sub-cooled condensate.

- Mode of Operation: Works intermittently to discharge condensate and is robust and resistant to water hammer.

- Integrated Non-Return Protection: Prevents reverse flow, ensuring stable system pressure.

- Heat Chamber: Designed to minimize the effects of weather conditions (such as low ambient temperatures, rain, and wind) on the trap’s performance.

- Strainers: Available with inside strainer (Fig. 640) or outside strainer (Fig. 641).

- Maintenance: The screwed cap is gasket-free for easy maintenance and quick installation.

Models and Material Options:

-

CONA® TD 640/641 PN40 (Forged Steel, High-Temperature Steel, Stainless Steel): Available in various material options based on application requirements. It’s designed for a nominal diameter range of DN15-25 (1/2" to 1") and has various connection options:

- Flanges

- Screwed sockets (Rp thread or NPT thread)

- Socket weld ends

- Butt weld ends

-

CONA® TD 641 PN63 (Stainless Steel): Suitable for higher pressure applications with DN10-25.

Pressure and Temperature:

- PN40 Models:

- Operating pressure up to 32 bar with inlet temperatures up to 450°C (for certain models).

- PN63 Models: Operating pressure up to 42 bar with inlet temperatures up to 450°C.

Installation & Options:

- Installation: Can be installed in any position.

- Strainer Options:

- Inside strainer (BR640)

- Outside strainer with blowdown valve (BR641 with optional valve for cleaning)

Software for Sizing:

- myValve®: A powerful software tool for valve sizing and project management, providing instant access to product data, order information, and more. The program supports both SI and ANSI units and helps in calculating steam trap systems.