Experience Unmatched Efficiency: Inverted bucket steam trap - ESU5 | Miyawaki

The Inverted bucket steam trap - ESU5 | Miyawaki is your trusted partner for industrial steam systems, delivering reliable performance and energy savings. This innovative steam trap is engineered for consistent operation, ensuring your equipment runs smoothly while minimizing maintenance demands. With the precision and quality you've come to expect from Miyawaki, the ESU5 helps keep your operations productive and cost-effective.

Key Features & Benefits of Inverted bucket steam trap - ESU5 | Miyawaki

- High Durability: Crafted from robust materials, the ESU5 stands up to harsh industrial environments, promising years of dependable service.

- Optimal Energy Use: It effectively removes condensation without letting steam escape, so you save on energy and eliminate waste.

- Automatic Function: The smart inverted bucket design works automatically, adjusting to pressure and load changes without manual involvement.

- Less Maintenance: Fewer moving parts mean less wear and tear, helping you reduce repair costs and downtime.

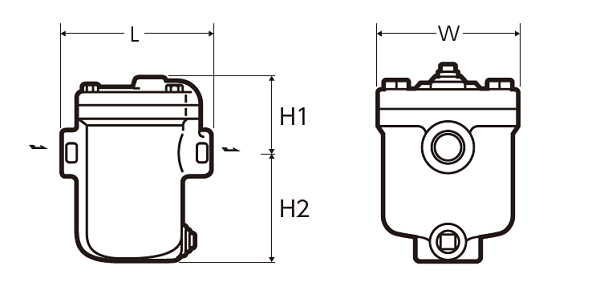

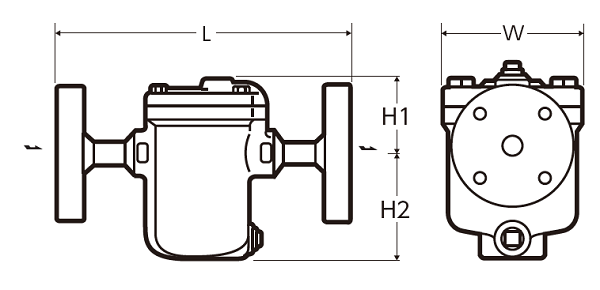

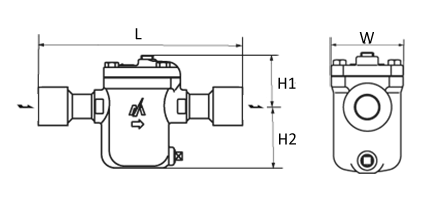

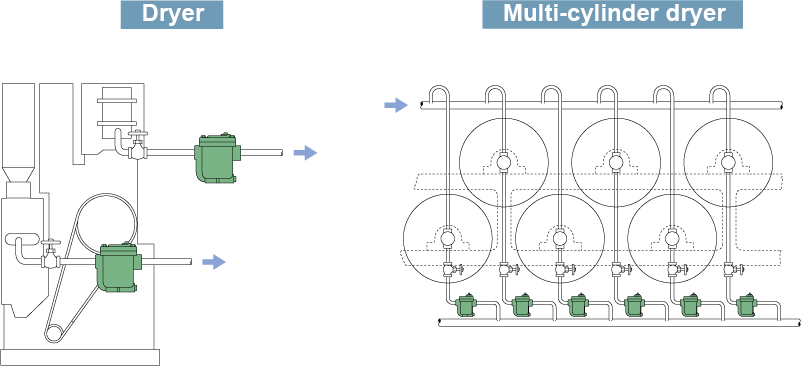

- Easy Installation: Thanks to its compact, straightforward construction, the ESU5 fits into your existing system quickly and effortlessly.

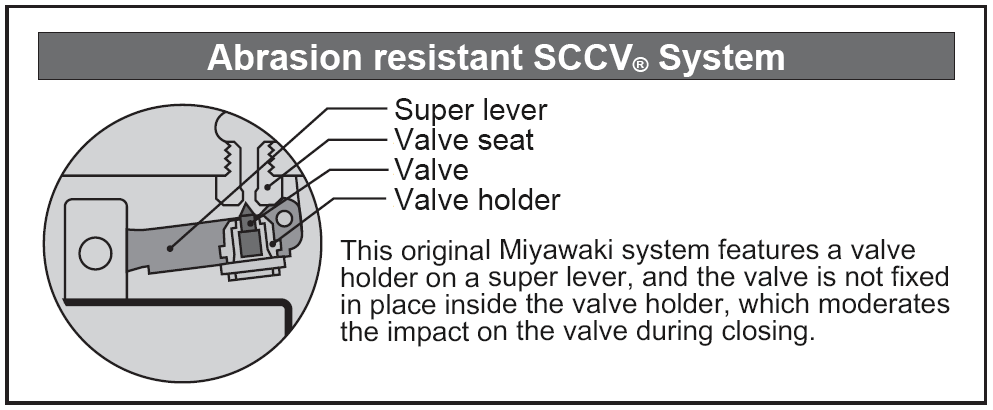

With the Inverted bucket steam trap - ESU5 | Miyawaki, you benefit from advanced features designed for hassle-free use. Its internal mechanism is resistant to water hammer and corrosion, two common challenges in industrial environments. The design allows for quick and effective drainage of condensate, preventing build-up that can put your equipment at risk. Plus, the ESU5 operates quietly, reducing noise in your facility so you can focus on what matters most.

Safety is a priority in every industrial setting, and the ESU5 is built with this in mind. Its reliable sealing system prevents leaks, safeguarding your workplace and maintaining system pressure. This steam trap is suitable for a wide range of pressures and loads, making it a versatile choice for various applications, from steam lines to process equipment.

Choose the Inverted bucket steam trap - ESU5 | Miyawaki for straightforward performance and peace of mind. Optimize your energy use, protect your machinery, and ensure smooth operation — all in one reliable unit built to last.