✅ Reversible pneumatic actuator with rolling diaphragm (max. air supply pressure: 6 bar)

✅ Electric actuators with manual override and overheat protection

✅ Interchangeable seat rings for easy maintenance

✅ Multiple plug designs for precise flow control

✅ Various sealing options, including PTFE, EPDM, and stainless steel bellows

✅ Available in nominal pressure ratings PN16, PN25, and PN40

✅ Leakage class IV – VI compliance (DIN EN 60534-4)

✅ Explosion-proof electric actuator versions available (ATEX-certified)

Technical Specifications

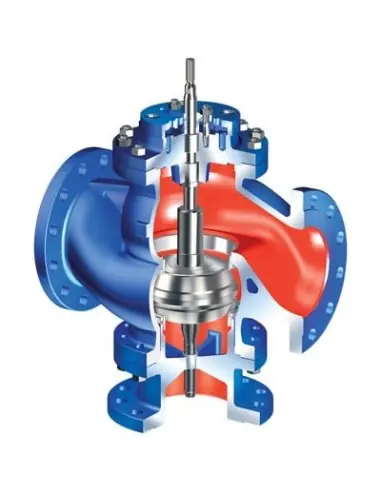

Valve Types & Configurations

- ARI-STEVI® 423 – Three-way control valve (mixing / diverting) with standard sealing options

- ARI-STEVI® 463 – Three-way control valve with stainless steel bellows for high-temperature applications

Material Options

| Model | Nominal Pressure | Material | Nominal Diameter (DN) |

|---|---|---|---|

| 12.423 / 12.463 | PN16 | EN-JL1040 | DN200-250 |

| 22.423 / 22.463 | PN16 | EN-JS1049 | DN200-250 |

| 22.423 | PN16 | EN-JS1049 | DN300 |

| 34.423 / 34.463 | PN25 | 1.0619+N | DN200-250 |

| 35.423 / 35.463 | PN40 | 1.0619+N | DN200-250 |

Other materials and custom versions available upon request.

Stem Sealing Options

| Model | Standard Sealing | Optional Sealing |

|---|---|---|

| 423 (DN200-300) | PTFE packing (-10°C to 250°C) | Pure graphite packing (-10°C to 450°C) |

| 423 (DN200-300) | EPDM sealing (-10°C to 150°C, suitable for water & steam up to 180°C) | -- |

| 463 (DN200-250) | Stainless steel bellows with graphite packing (-60°C to 450°C) | Stainless steel bellows with EPDM sealing (-60°C to 150°C, suitable for water & steam up to 180°C) |

Pressure & Temperature Ratings

| Material | PN Rating | Temperature Range | Max Operating Pressure |

|---|---|---|---|

| EN-JL1040 | PN16 | -10°C to 120°C | 16 bar |

| EN-JS1049 | PN16 | -10°C to 200°C | 16 bar |

| EN-JS1049 | PN25 | -10°C to 200°C | 25 bar |

| 1.0619+N | PN25 | -60°C to 400°C | 25 bar |

| 1.0619+N | PN40 | -60°C to 400°C | 40 bar |

| 1.4408 | PN40 | -60°C to 450°C | 40 bar |

Plug Designs & Flow Performance

- Mixing plug (with two screwed seat rings) – Standard for mixing applications (2 inlets, 1 outlet)

- Diverting plug (with two screwed seat rings) – Used exclusively for diverting service (1 inlet, 2 outlets)

- Parabolic plug with metal seat – Leakage Class IV (DIN EN 60534-4)

- V-port plug with metal seat – Leakage Class IV (DIN EN 60534-4)

Actuation Options

Pneumatic Actuator – ARI-DP 34 / 34T

- Max Air Supply Pressure: 6 bar

- Spring-opening or spring-closing function

- Handwheel for manual operation available (optional)

Electric Actuator – ARI-PREMIO / PREMIO-Plus 2G

- Digital actuator control with BLDC technology

- Protection Class: IP65

- Handwheel for emergency operation

- Integrated torque and travel switches

- Explosion-proof models available (ATEX-certified)

Electric Actuator – AUMA SAR (MATIC)

- Protection Class: IP67

- 2 torque and 2 travel switches

- Overheating protection for motor as standard

- Explosion-proof version available upon request