General Features:

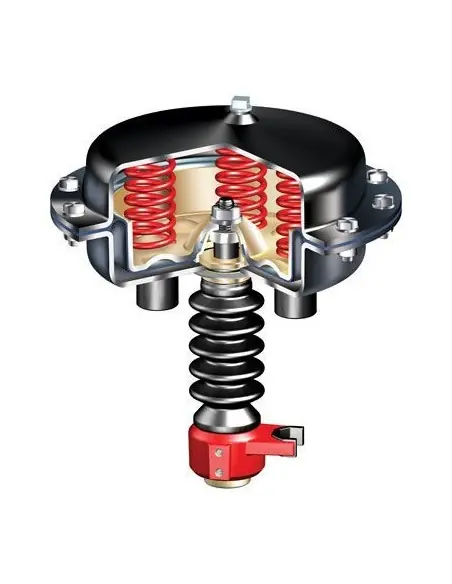

- Compact design with an actuator featuring a rolling diaphragm.

- Mountable in any position.

- Maximum air supply pressure: 6 bar.

- Travel: up to 120 mm.

- Direct or reverse acting for models DP32-34.

- Burnished stem protected by a bellow.

- Maintenance-free O-ring sealing with flexible guiding.

- Operational ambient temperatures: From -10°C to +80°C (for DP32-34Tri, optional -50°C to +80°C).

- Favorable size/performance ratio.

Operating Modes:

- Spring closes on air failure (stem extending by spring).

- Spring opens on air failure (stem retracting by spring).

Materials and Construction:

- Stem: Made from materials like X20Cr13+QT, 1.4021+QT, 1.4571.

- Seals: EPDM50, 42CR, NBR.

- Spring plate: FSt (Fe/Zn8M), FSt (Fe/NiP50).

- Diaphragm material: NBR with webbing.

- Housing: DD13+QT or 1.0335+QT, with optional C5-M coating for added corrosion resistance.

Thrust and Performance:

- DP30: Suitable for spring range between 2.2 to 4.5 bar with a thrust of 2000 N.

- DP32: Suitable for spring range between 0.2 to 3.8 bar with thrusts ranging from 490 N to 4900 N.

- DP33: Higher thrust options with spring range from 0.2 to 4.0 bar and up to 8970 N.

- DP34: Larger thrust options with a spring range from 0.2 to 4.0 bar with thrust up to 18840 N.

- DP34T: Enhanced for higher performance with dual spring design, reaching 47100 N thrust.

Dimensions and Weights:

- DP30: Diameter of 168 mm with a weight of 5 kg.

- DP34T: Diameter of 405 mm with a weight of 116 kg.

- DP35: Diameter of 755 mm with a weight of 325 kg.

Accessories:

- Top-mounted handwheel for manual operation.

- 3/2-way solenoid valves with manual operating device.

- Throttling valves to increase operation time.

- Check valve with throttling function.

- Lock-up valve for holding air in the actuator during air failure.

- Air set with gauge to reduce air pressure and remove dust and water droplets.

- Limit switches (electrical, mechanical, inductive) for denoting the end of travel.

- Position indicators for analog feedback of valve positions.

Special Designs:

- Actuators for sub-zero temperatures (-40°C to +80°C).

- Actuators for aggressive environments.

- Short design actuators and short design handwheels for space-saving installations.

Application and Setup:

- The DP series actuators are designed to be mounted directly on control valves and stop valves.

- The actuators convert pneumatic pressure into linear travel, offering short lifting times (1-10 seconds) on air supply or air failure.