Plate Ηeat Εxchangers

Heat Exchangers

Heat exchangers are essential devices in many industries, designed to move heat from one substance to another efficiently. In industrial settings, they help control temperatures, making processes safer and more productive. Whether you’re managing a factory, a power plant, or any other industrial facility, heat exchangers play a key role in ensuring equipment runs smoothly and energy is used wisely.

These devices work in a simple but effective way. They transfer heat between fluids—like liquids or gases—without mixing them together. For example, in a chemical plant, a heat exchanger can cool down hot chemicals before they move on to the next stage. In power plants, they help turn steam back into water so the process can repeat efficiently. By keeping temperatures steady, heat exchangers help prevent overheating, save energy, and reduce costs.

There are several types of heat exchangers, including plate heat exchangers, shell-and-tube designs, and air-cooled versions. Each type is suited for different needs and environments. Choosing the right one depends on factors like the temperatures involved, the materials being used, and the space available.

Thanks to their reliability and effectiveness, heat exchangers are a smart investment for any industrial setup that relies on temperature control. They help keep operations safe, efficient, and cost-effective.

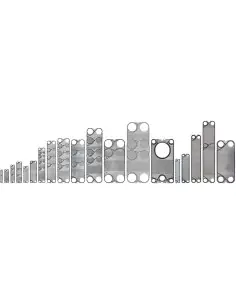

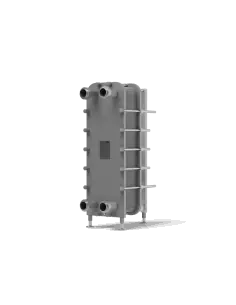

Plate Ηeat Εxchangers

Plates for Heat Exchangers | SonFlow

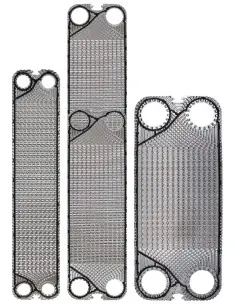

Plate Ηeat Εxchangers

Plate Heat Exchangers Certified by AHRI | SonFlow

Plate Ηeat Εxchangers

Brazed Plate Heat Exchangers | SonFlow

Plate Ηeat Εxchangers

Free Flow Plate Heat Exchanger | SonFlow

Evaporators

Condenser/Evaporator | SonFlow

Plate Ηeat Εxchangers

Standard plate heat exchangers | Sondex/Danfoss

Plate Ηeat Εxchangers

Brazed plate heat exchangers | Sondex/Danfoss

Plate Αnd Shell Exchangers

Plate & shell heat exchangers | Sondex/Danfoss

Spiral Heat Exchangers

Spiral heat exchangers | Sondex/Danfoss

Plate Ηeat Εxchangers

Free Flow plate heat exchangers | Sondex/Danfoss

Plate Ηeat Εxchangers