Brazed Plate Heat Exchangers | SonFlow: Advanced Solutions for Efficient Industrial Heating and Cooling

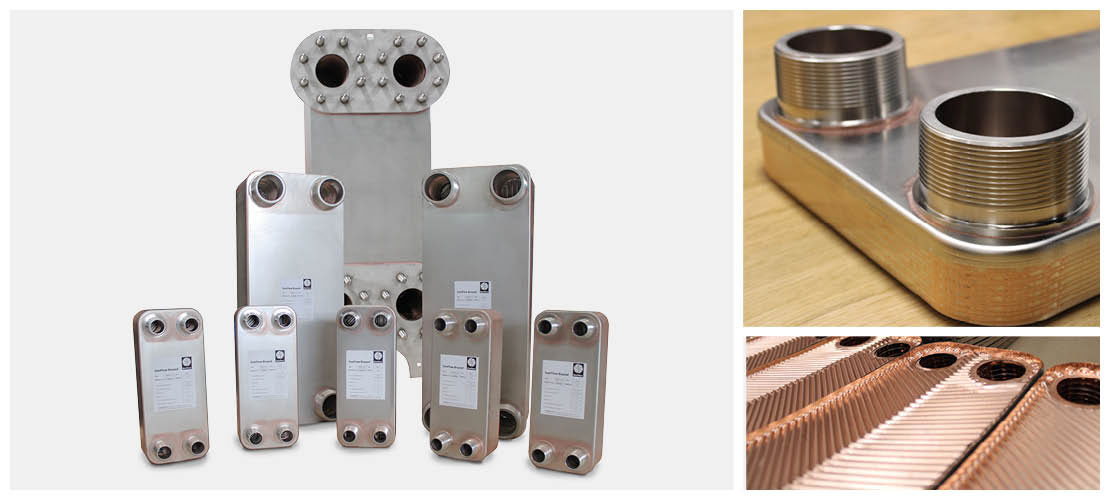

Experience exceptional performance with the Brazed Plate Heat Exchangers | SonFlow—an industry-leading device designed for superior heat transfer in demanding environments. Engineered for industrial use, this compact and robust heat exchanger guarantees top efficiency, reliability, and long-lasting durability in every application.

Features & Benefits of Brazed Plate Heat Exchangers | SonFlow

- Maximum Efficiency: Precise plate design ensures rapid heat transfer, minimizing energy loss and saving operational costs.

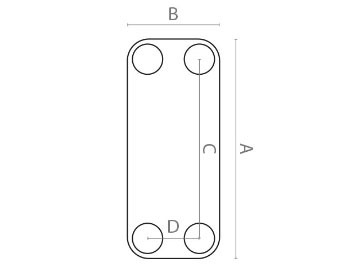

- Space-Saving Design: The compact structure is ideal for installations where space is limited, making it suitable for both new systems and upgrades.

- Durable Construction: Made with high-quality stainless steel and copper brazing, it offers superb resistance to high pressure and temperature, reducing downtime and maintenance needs.

- Easy Maintenance: The streamlined build prevents clogging and simplifies cleaning, keeping your processes running smoothly with minimal intervention.

- Versatile Applications: Perfect for a wide range of industrial processes, such as HVAC, refrigeration, oil cooling, and heat recovery systems.

The Brazed Plate Heat Exchangers | SonFlow stand out with their advanced plate profiles, which optimize contact between fluids for quick and effective heat exchange. This means less energy is required to reach the desired temperature, making your operation more cost-effective.

Installation is straightforward, and the exchanger’s small footprint allows it to fit easily into existing setups without complex adjustments. Its robust design withstands pressures up to 30 bar and temperatures up to 200°C, ensuring safe and reliable performance even in heavy-duty conditions.

With a focus on sustainability, the Brazed Plate Heat Exchangers | SonFlow promote energy savings and lower emissions, supporting environmentally friendly operations. Each unit undergoes rigorous quality checks to guarantee leak-proof operation and consistent results over years of continuous use.

Choose Brazed Plate Heat Exchangers | SonFlow for your industrial thermal management needs and benefit from reduced costs, increased productivity, and peace of mind.