Plates for Heat Exchangers | SonFlow: Elevate Industrial Efficiency

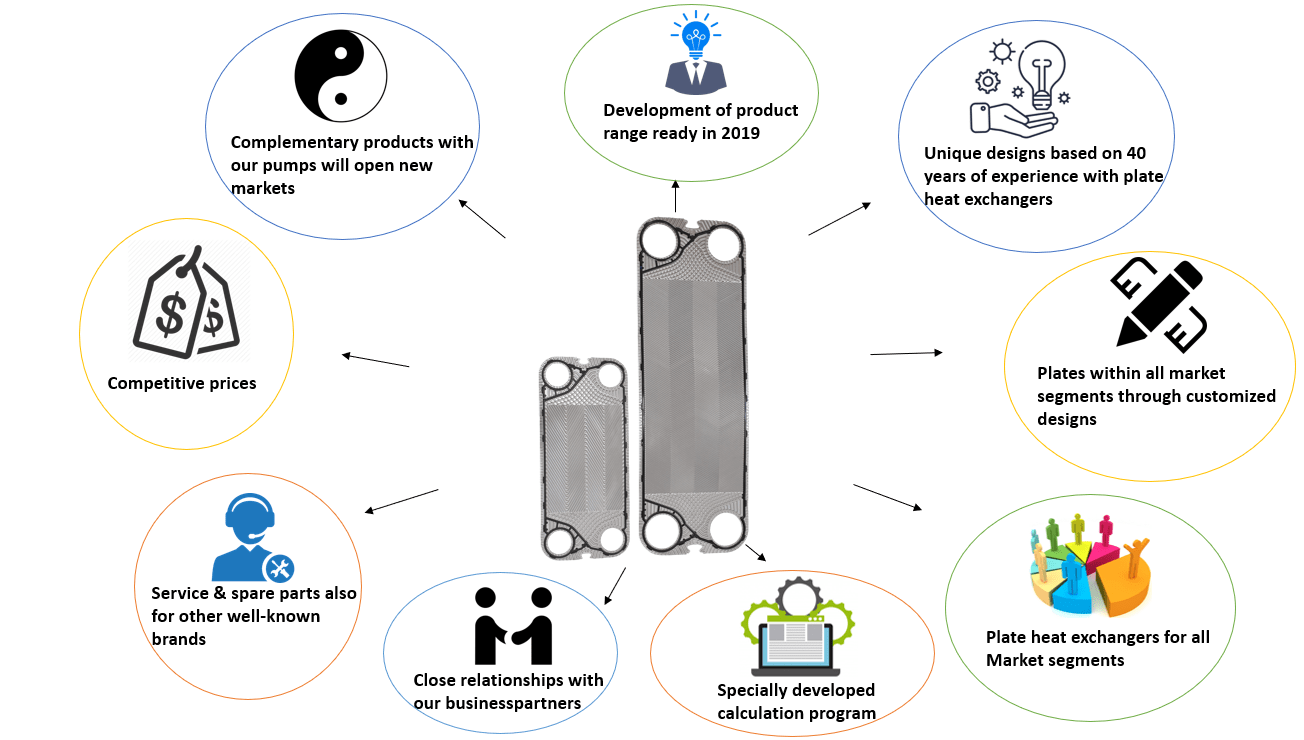

Transform the performance of your heating and cooling processes with the Plates for Heat Exchangers | SonFlow. Crafted for durability and unmatched efficiency, these plates are the backbone of modern industrial heat exchangers, ensuring that your operations run smoother, faster, and more reliably.

A Step Ahead: Features & Benefits of Plates for Heat Exchangers | SonFlow

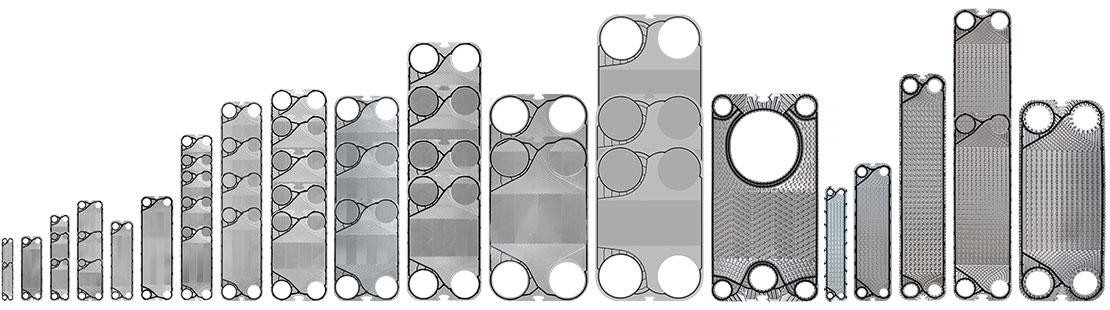

- Superior Heat Transfer: Each plate is expertly designed with advanced corrugated patterns, maximizing surface area and boosting heat transfer efficiency. This means less energy is needed and processes complete faster.

- Robust Construction: Built from high-quality stainless steel, these plates handle challenging industrial environments with ease. They resist corrosion and wear, reducing maintenance frequency and downtime.

- Easy Maintenance: The plates are engineered for quick assembly and disassembly, allowing for straightforward cleaning and inspection. This minimizes shutdown time and keeps operations running smoothly.

- Leak-Resistant Seals: Precision-fitted gaskets provide excellent sealing, preventing leaks and ensuring safe, continuous operation even under demanding conditions.

- Flexible Compatibility: Designed to fit a wide range of heat exchanger models, SonFlow plates make upgrades and replacements simple—no need for complicated adjustments.

From food processing plants to chemical facilities, these plates deliver consistent performance. Their advanced design ensures that heat is exchanged quickly and efficiently, saving both energy and operational costs. With less energy wasted, you can expect a direct benefit to your bottom line.

The Plates for Heat Exchangers | SonFlow also stand out for their long lifespan. Built to withstand the rigors of industrial use, they maintain their impeccable performance year after year, making them a smart and sustainable choice for your equipment needs.

Upgrade your heat exchanger with Plates for Heat Exchangers | SonFlow and experience the difference in reliability, efficiency, and long-term savings. Invest in proven technology that keeps your systems at peak performance day after day.