Efficient Performance in Every Drop: Standard plate heat exchangers | Sondex/Danfoss

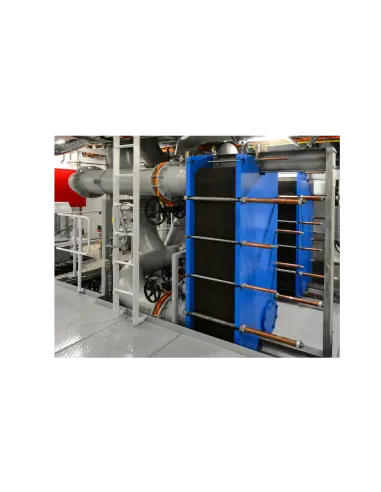

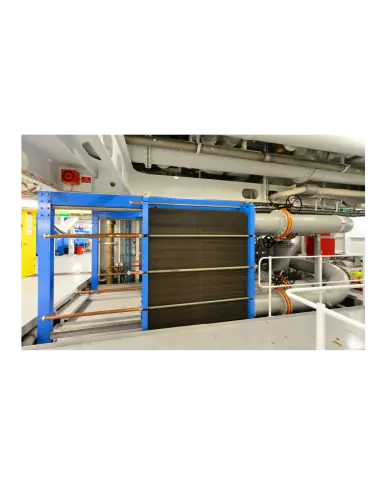

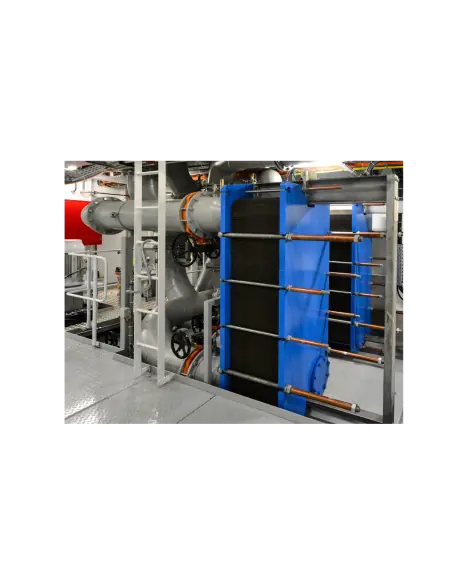

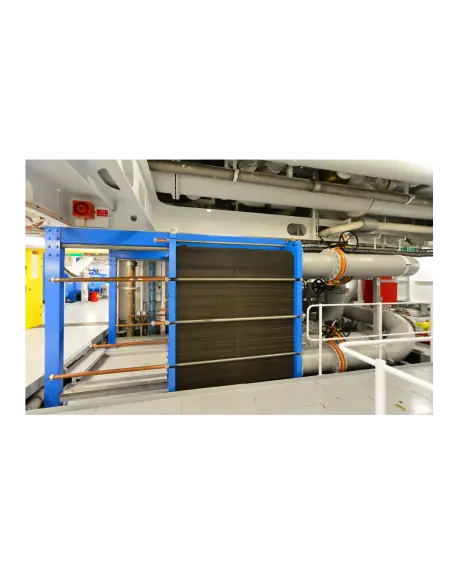

Experience the next level of heat transfer with the Standard plate heat exchangers | Sondex/Danfoss. Designed for industrial reliability, these cutting-edge exchangers are a smart choice for any company seeking consistent, high-quality thermal solutions. Built with precision, they offer efficiency, adaptability, and trusted performance in demanding environments.

Key Features & Benefits of Standard plate heat exchangers | Sondex/Danfoss

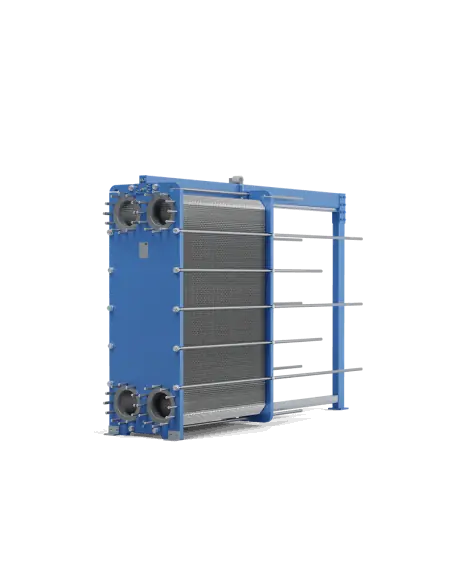

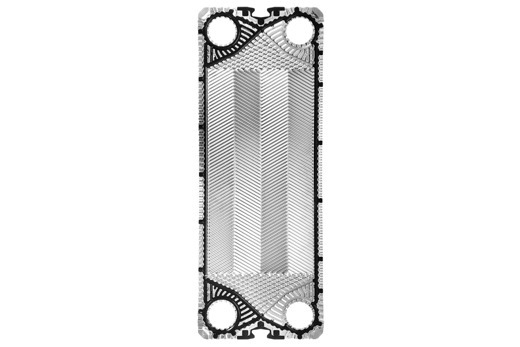

- Superior Heat Transfer: Each plate is expertly engineered to maximize surface area, ensuring exceptional energy exchange between fluids. This means less energy waste and more savings on your utility bills.

- Flexible Configuration: Adapt to any industrial process quickly. The modular plate design allows for rapid adjustments or expansions, making it simple to meet your specific needs as your operations grow.

- Compact and Space-Saving: The slim profile fits easily into limited spaces while still delivering strong performance. Free up valuable floor space without sacrificing capacity.

- Easy Maintenance: Designed for straightforward service, the exchangers can be opened for cleaning and inspection without complicated tools or downtime, keeping your process running smoothly.

- Leak-Proof Operation: Advanced sealing technologies ensure tight, reliable performance under high pressure, preventing leaks and reducing maintenance costs.

- Durable Construction: Built with high-quality, corrosion-resistant materials, these exchangers withstand tough industrial conditions, ensuring a long service life.

The Standard plate heat exchangers | Sondex/Danfoss are engineered to handle a wide variety of fluids, from water and oil to chemicals and food products. Their design guarantees even flow distribution, preventing hotspots and minimizing fouling. This ensures not only consistent results but also reduces the need for frequent cleaning or repairs.

Easy to install and reliable in operation, these plate heat exchangers bring peace of mind to facility managers and engineers alike. They support higher sustainability goals by cutting down on energy consumption, making them a responsible solution for modern industry.

Upgrade your thermal processes with the trusted performance of Standard plate heat exchangers | Sondex/Danfoss—where efficiency meets innovation for lasting value.