Discover the Excellence of Plate & Shell Heat Exchangers | Sondex/Danfoss

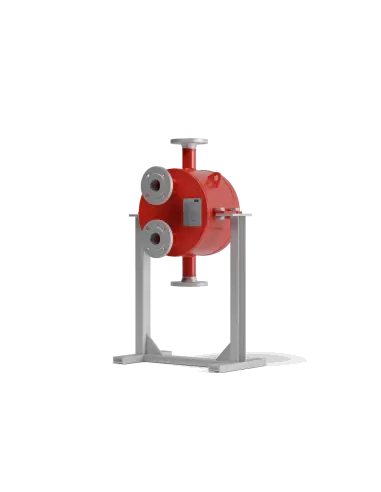

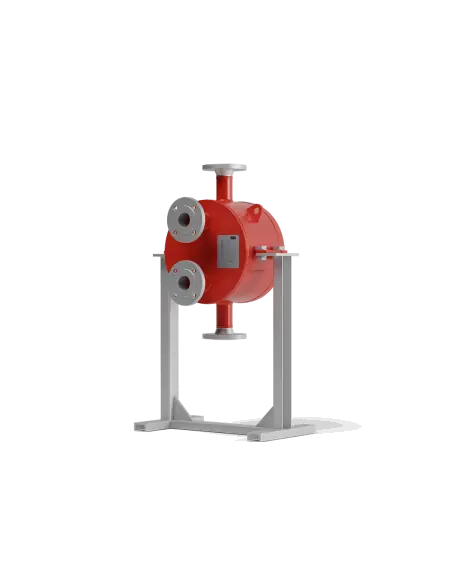

Upgrade your industrial operations with the Plate & Shell Heat Exchangers | Sondex/Danfoss – an innovative solution designed to deliver reliable and efficient heat transfer even under the toughest conditions. Expertly engineered for demanding environments, this heat exchanger blends durability with impressive performance, making it the go-to choice for a wide range of industries.

Features & Benefits of Plate & Shell Heat Exchangers | Sondex/Danfoss

- Superior Heat Transfer: The advanced plate design enables fast and effective heat exchange by maximizing the contact surface, ensuring consistent performance with every use.

- Robust Construction: Made from high-quality materials, this heat exchanger is built to last. It withstands high pressures and temperatures, ensuring longevity and reliability.

- Compact Design: Save valuable space without sacrificing power. Its space-saving build makes it ideal for installations with limited room.

- Easy Maintenance: Convenient access for inspection and cleaning means reduced downtime and more efficient operation. A smart choice for busy industrial settings.

- Wide Application: Perfect for industries such as power generation, chemical processing, refrigeration, and more. Adaptable to a variety of fluids and system requirements.

With Plate & Shell Heat Exchangers | Sondex/Danfoss, you benefit from a seamless combination of reliability and advanced technology. The unique plate and shell structure offers low pressure loss and excellent energy efficiency, which can reduce operational costs over time. Its user-friendly design means anyone can operate and maintain it with ease, regardless of technical experience.

Make your industrial processes smoother, safer, and more cost-effective. Choose the Plate & Shell Heat Exchangers | Sondex/Danfoss for outstanding results and peace of mind every single day.