Unlock Reliable Performance with Free Flow plate heat exchangers | Sondex/Danfoss

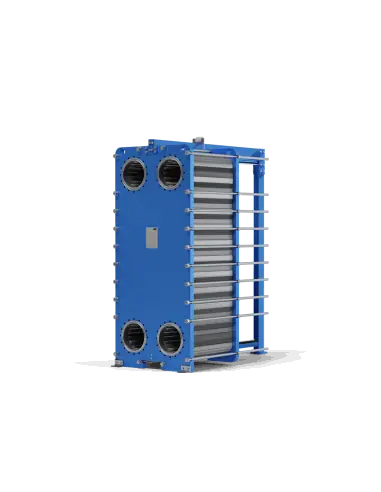

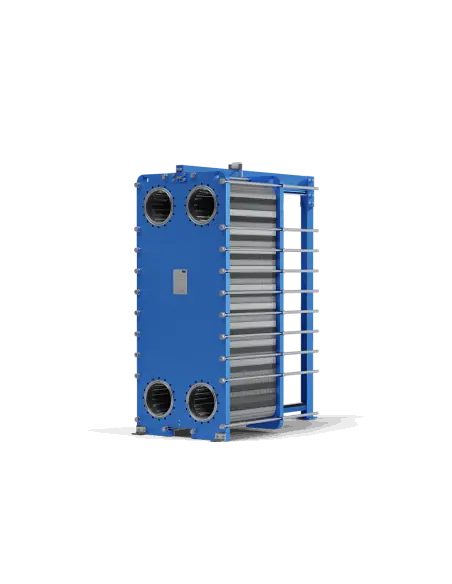

Boost the efficiency of your industrial operations with the Free Flow plate heat exchangers | Sondex/Danfoss. These robust units are engineered to handle demanding processes, making them the ultimate choice for industries looking to optimize their heat transfer capabilities, even when working with challenging and contaminated liquids. Designed with simplicity and durability in mind, they guarantee a seamless solution for unique heat exchange needs.

Key Features & Benefits of Free Flow plate heat exchangers | Sondex/Danfoss

- Unmatched Versatility: Easily process viscous, high-fiber, or particle-rich fluids without frequent maintenance. These plate heat exchangers are ideal for pulp & paper, wastewater, and various heavy-duty industrial applications where conventional designs fall short.

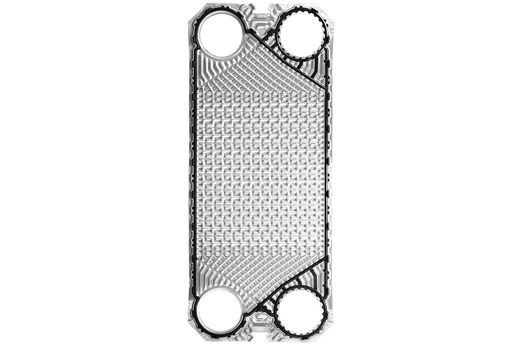

- Clog-Resistant Innovation: The unique free flow plate pattern ensures wide channels for unimpeded flow. Enjoy peace of mind knowing there’s minimal risk of clogging, significantly reducing downtime and keeping your operations running smoothly.

- Optimal Heat Transfer: The smart plate design maximizes surface area while promoting turbulent flow, ensuring excellent heat exchange efficiency, even with dirty or thick media.

- Easy Maintenance: Simplified access to plates allows for quick inspection and cleaning, helping you meet sanitation and quality standards effortlessly.

- Custom Fit: Free Flow plate heat exchangers | Sondex/Danfoss can be tailored to your process requirements, guaranteeing the perfect match for your operation, regardless of scale or media type.

- Robust Construction: Made with premium materials, these exchangers stand up to harsh environments and tough conditions, offering long-lasting, reliable performance.

Choose Free Flow plate heat exchangers | Sondex/Danfoss to experience advanced heat transfer technology designed with the end user in mind. Streamline maintenance, minimize energy waste, and handle the trickiest fluids with ease. When you need a dependable solution for industrial fluid management, this equipment delivers consistent results and peace of mind, every step of the way.