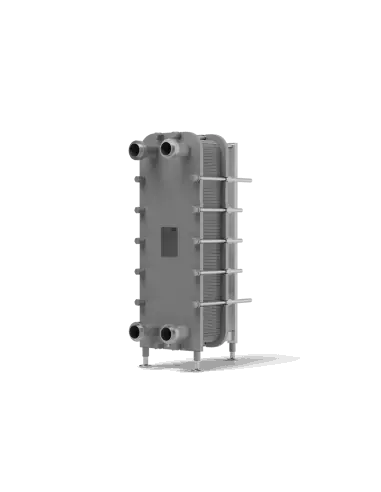

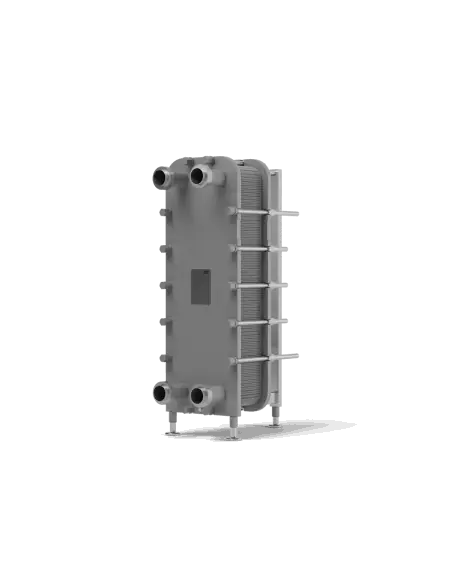

Sanitary Plate Heat Exchangers | Sondex/Danfoss: The Ideal Choice for Industrial Efficiency

Discover how the Sanitary Plate Heat Exchangers | Sondex/Danfoss are redefining industrial heat transfer. Specifically designed for the demands of hygienic applications, these plate heat exchangers deliver superior performance and unmatched cleanliness, making them a top solution for industries like food processing, pharmaceuticals, and beverages.

Features & Benefits of Sanitary Plate Heat Exchangers | Sondex/Danfoss

- Outstanding Hygiene: With smooth, easy-to-clean surfaces, these units ensure no residues are left behind, protecting your products and processes from contamination.

- Easy Maintenance: The design allows for quick disassembly, reducing downtime and simplifying routine cleaning, which keeps your operations running smoothly.

- Maximum Efficiency: Engineered plate patterns maximize heat transfer, saving energy and reducing operating costs without sacrificing reliability.

- Customizable: Available in various sizes and configurations to fit your specific process needs, offering flexible solutions for both small and large-scale applications.

- Durable Materials: Manufactured from high-grade stainless steel, ensuring long-lasting performance and resistance to harsh cleaning agents or production environments.

Using Sanitary Plate Heat Exchangers | Sondex/Danfoss, you gain peace of mind with reliable temperature control and consistent product quality. Their advanced engineering provides optimum heat exchange, which translates to faster processing times and better throughput for your business.

Upgrading to these exchangers means easier compliance with strict industry standards, thanks to their sanitary design and certification options. Installation is straightforward, and the compact footprint saves space in your facility.

Choose Sanitary Plate Heat Exchangers | Sondex/Danfoss for a cleaner, safer, and more efficient solution to your industrial heating and cooling challenges.