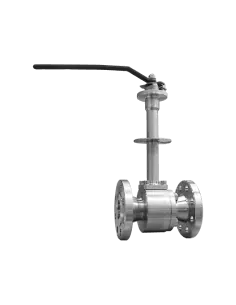

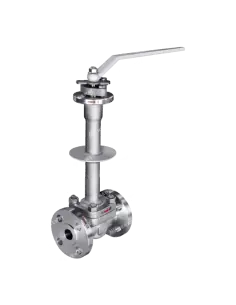

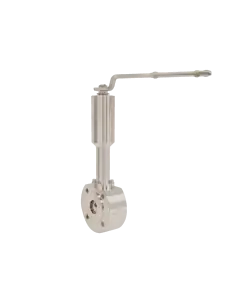

Cryogenic

Cryogenic ball valves are essential components for handling very low-temperature liquids and gases in various industrial settings. These valves are specially designed to perform reliably in extreme cold, often as low as minus 196 degrees Celsius, making them a popular choice for industries like LNG (liquefied natural gas), petrochemical plants, and chemical processing. Their main role is to control the flow of cryogenic fluids with safety and efficiency.

What sets cryogenic ball valves apart is their robust construction and unique features that prevent leaks, even under intense pressure and freezing temperatures. Unlike standard valves, they use materials that can withstand thermal shock and ensure a tight seal when opened or closed. This helps maintain the integrity and purity of sensitive cryogenic substances.

The quick quarter-turn action of the ball inside the valve makes operation fast and easy, offering precise control over the flow. Many models also come with extended stems, so workers can operate the valve safely from a distance, reducing the risk of frostbite or injury.

Cryogenic ball valves are built to last and require minimal maintenance, even in challenging environments. They play a crucial role in keeping operations safe and running smoothly where extreme cold is a constant factor.

Cryogenic