Features:

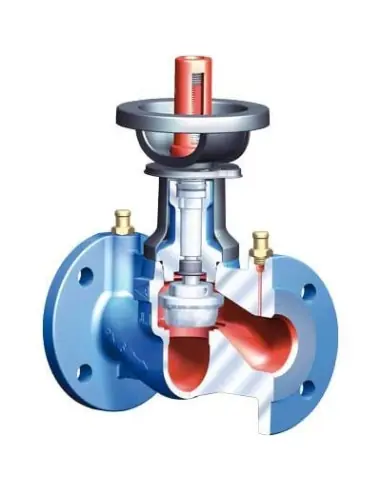

- Straight-through valves with flanges and various sealing options (special stem seal, gland seal, and bellows seal).

- Maintenance-free operation.

- Soft sealing and metal-sealed versions.

- Digital display for monitoring and control.

- Insulating cap with an integrated dew point barrier.

- Travel limiter and non-rotation lock for improved control.

- Position indicator as standard.

Models:

- ARI-ASTRA® (DN15-200) – Straight-through with special stem seal (grey cast iron)

- ARI-ASTRA® (DN250-500) – Straight-through with gland packing (grey cast iron)

- ARI-ASTRA®Plus (DN15-200) – Straight-through with bellows seal (SG iron)

- ARI-ASTRA®Plus (DN250-400) – Straight-through with gland packing (SG iron)

Materials:

- Body: Grey cast iron (EN-JL1040, EN-GJL-250), SG iron (EN-JS1049, EN-GJS-400-18U-LT)

- Stem: Stainless steel (X20Cr13+QT, 1.4021+QT)

- Sealing: PTFE, EPDM, Pure graphite for packing

Performance & Dimensions:

- Nominal Diameter: From DN15 to DN500 depending on model

- Pressure Rating: PN16, PN25

- Kvs Values: Ranges from 4.5 m³/h (DN15) to 3185 m³/h (DN500)

- Temperature Range:

- For ARI-ASTRA®: From -10°C to +120°C (up to +130°C for short periods)

- For ARI-ASTRA®Plus: From -10°C to +175°C (up to +350°C for some models)

Travel Limitation and Indicators:

- Travel Limiter for all nominal diameters

- Digital display for easy flow control

- Pressure gauge stud (optional for some models)

Applications:

These valves are typically used in:

- Flow regulation for industrial systems such as chemical processing, HVAC, water treatment, and energy systems.

- Temperature and flow management in pipelines.

- Pressure control for various gases, liquids, and steam systems.

Additional Accessories:

- Balancing Instrument ARImetec®-DX for flow and differential pressure measurement in hydraulic systems.

- Sensor device and hand terminal for flow regulation and measurement.

Flange Dimensions & Pressure-Temperature Ratings:

- Flanges conform to DIN EN 1092-2 standard.

- Pressure-temperature ratings vary based on material and temperature, with EN-JL1040 having a maximum of 16 bar at 120°C and EN-JS1049 able to handle 16 bar up to 350°C.