Innovative Steam Control: Inverted bucket steam trap - ESH21 | Miyawaki

Discover unmatched reliability with the Inverted bucket steam trap - ESH21 | Miyawaki, designed for efficient steam management in demanding industrial environments. Engineered for longevity and consistent performance, this trap ensures your steam system runs smoothly, conserves energy, and minimizes costs.

Features & Benefits of the Inverted bucket steam trap - ESH21 | Miyawaki

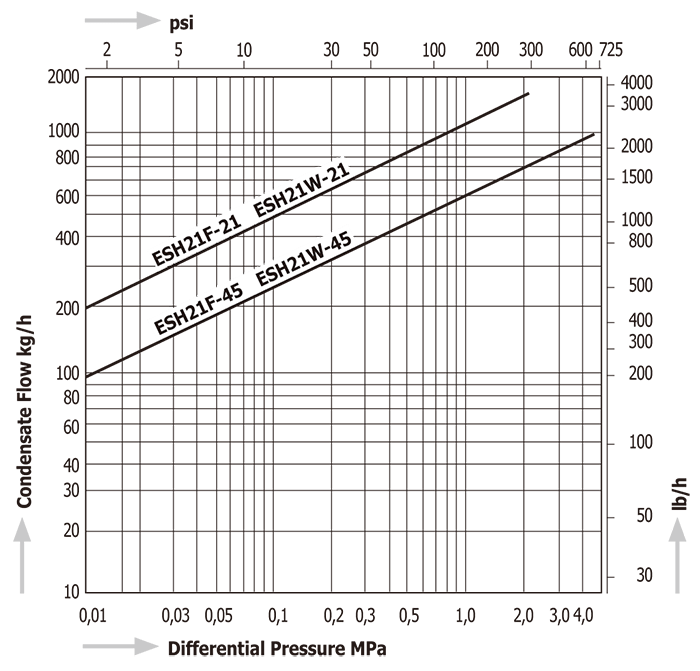

- Dependable Operation: The inverted bucket design offers automatic removal of condensate without wasting steam, keeping your processes running smoothly and efficiently.

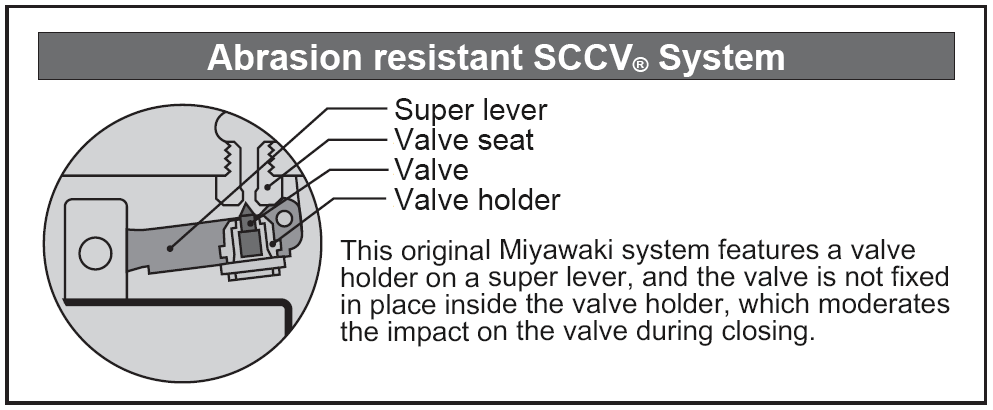

- Durable Construction: Built with high-quality stainless steel components, the ESH21 withstands harsh conditions and guarantees long-term performance with minimal maintenance.

- Energy Efficiency: By precisely separating condensate and steam, the ESH21 reduces steam losses and saves energy, which directly translates into lower operational costs.

- Corrosion Resistance: Specially selected materials protect the trap from rust and corrosion, ensuring a longer service life even in aggressive industrial atmospheres.

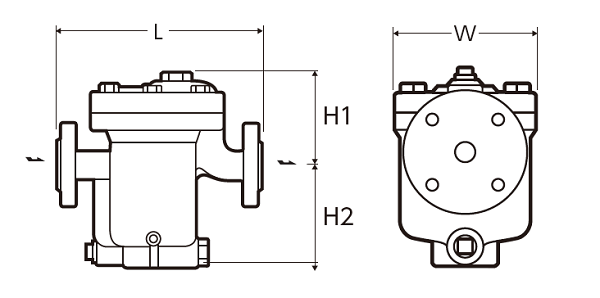

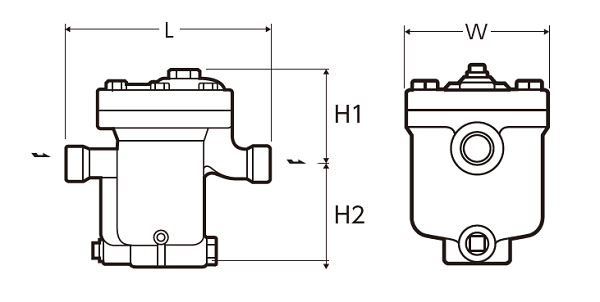

- Easy Installation and Maintenance: Compact and lightweight, the trap can be fitted easily into new or existing systems. Simple design means maintenance is quick, with minimal downtime.

- Consistent Performance: The ESH21 operates reliably under variable loads and pressures, providing consistent condensate discharge without needing frequent adjustments.

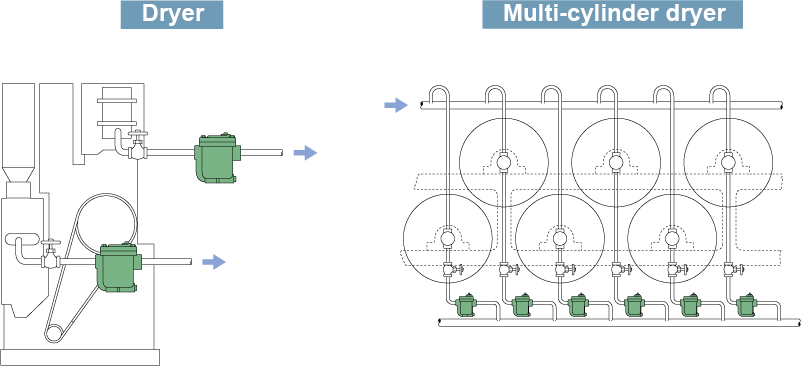

- Versatile Application: Suitable for a range of steam applications, from heating to process lines, giving you flexibility across different industrial settings.

The Inverted bucket steam trap - ESH21 | Miyawaki brings advanced technology to your steam system, making it easy to control and manage steam—no technical background needed. Its self-acting mechanism ensures water is removed while valuable steam stays in the system, maximizing efficiency. Choose ESH21 for a long-lasting, worry-free solution that keeps your operations at peak performance.