Inverted bucket steam trap - ER25 | Miyawaki: Efficiency for Reliable Steam Systems

The Inverted bucket steam trap - ER25 | Miyawaki is a trusted solution for industrial steam management, designed to enhance system performance and ensure energy efficiency. Built with precision and reliability in mind, the ER25 makes handling steam and condensate simple, safe, and effective, helping you get the most out of your steam processes.

Top Features and Benefits of the Inverted bucket steam trap - ER25 | Miyawaki

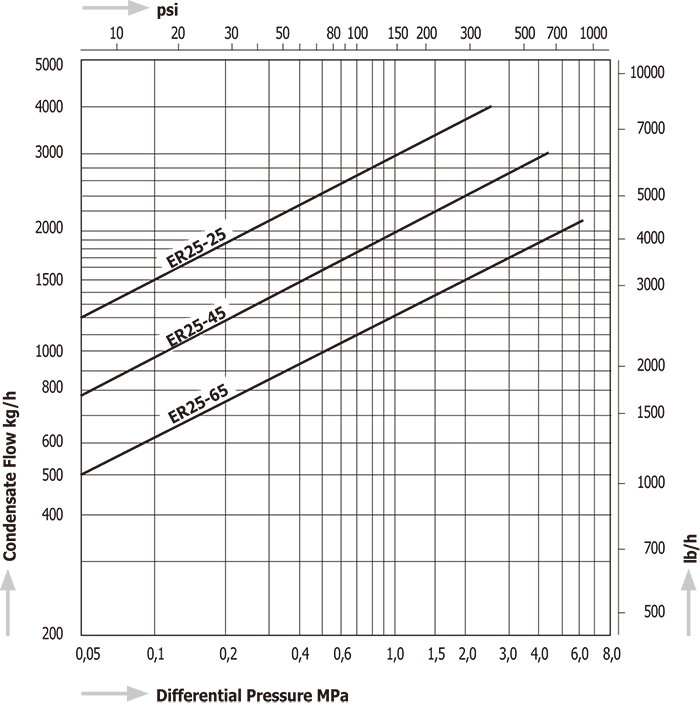

- Energy Savings: The ER25 reduces wasted steam by releasing only condensate and non-condensable gases, helping you cut down on unnecessary energy costs.

- Robust Design: Its sturdy construction ensures long life and resistance to wear, even in tough industrial environments. This means fewer interruptions and less maintenance.

- Consistent Performance: The inverted bucket mechanism gives you reliable operation, quickly responding to changes in steam flow for stable and efficient performance.

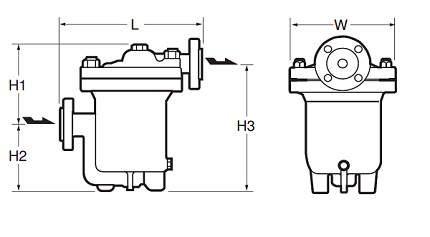

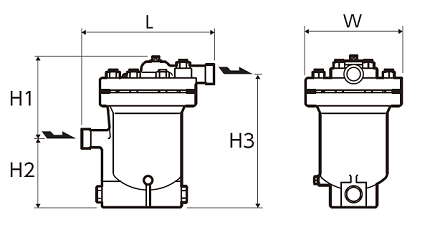

- Easy Installation: With a compact form and straightforward setup, the ER25 is simple to install into existing steam systems, minimizing downtime during upgrades.

- Protection for Equipment: Efficient removal of condensate helps prevent water hammer and corrosion, extending the lifespan of expensive machinery and piping.

- Low Maintenance: Designed for trouble-free operation, the ER25 requires minimal attention, letting your team focus on other priorities.

The Inverted bucket steam trap - ER25 | Miyawaki works by using a floating internal bucket to separate steam from water. When condensate enters the trap, the bucket sinks and opens a valve to discharge the unwanted water. When steam is present, the bucket floats, closing the valve and keeping valuable steam within the system. This efficient process means the ER25 works only when needed, saving energy and reducing waste.

Industries rely on the ER25 for its durability and dependable performance. Whether used in heating, processing, or steam distribution applications, it helps maintain a safe and effective environment. With the ER25, you protect your investment and maximize productivity.

Choose the Inverted bucket steam trap - ER25 | Miyawaki for a proven and uncomplicated way to boost steam system efficiency, lower costs, and ensure peace of mind.