Reliable Performance with the Inverted bucket steam trap - ESH8N | Miyawaki

Experience dependable steam management with the Inverted bucket steam trap - ESH8N | Miyawaki, designed exclusively for industrial applications. This robust device streamlines your steam system, ensuring you enjoy high efficiency and protection for your valuable equipment. With advanced engineering and user-friendly features, the ESH8N delivers trouble-free operation and easy maintenance while maximizing energy savings.

Features & Benefits of the Inverted bucket steam trap - ESH8N | Miyawaki

- Consistent Operation: The ESH8N uses a highly-efficient inverted bucket mechanism that reliably removes condensate and air from your steam lines, keeping the process running smoothly.

- Energy Efficiency: By discharging only unwanted condensate, it prevents steam loss and helps lower your operational costs.

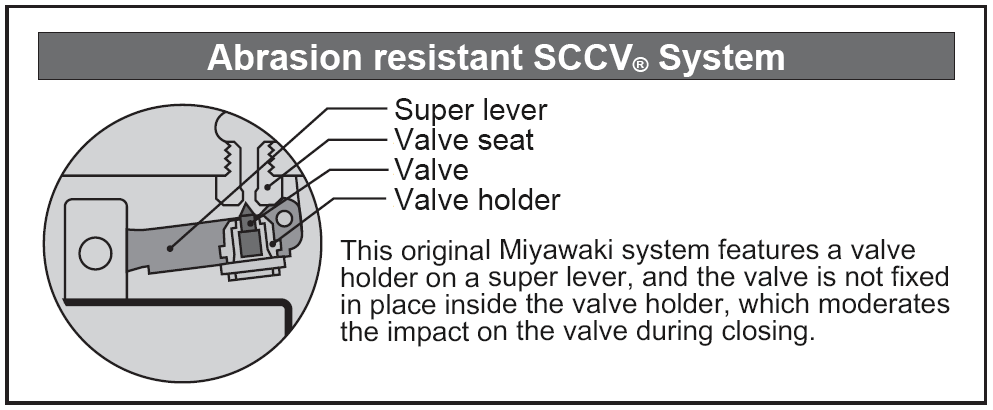

- Durable Construction: Built with high-quality stainless steel internals, the ESH8N offers exceptional resistance to corrosion and wear, extending the lifespan of your steam system.

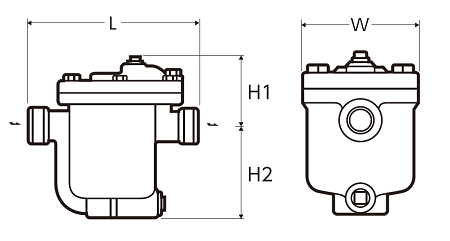

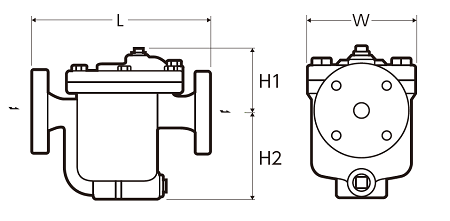

- Simple Installation & Maintenance: The compact design fits easily into most piping layouts, while its straightforward structure allows for quick servicing, reducing downtime.

- Automatic Air Venting: Effective air discharge ensures that your steam reaches its destination quickly, improving heating efficiency and system response times.

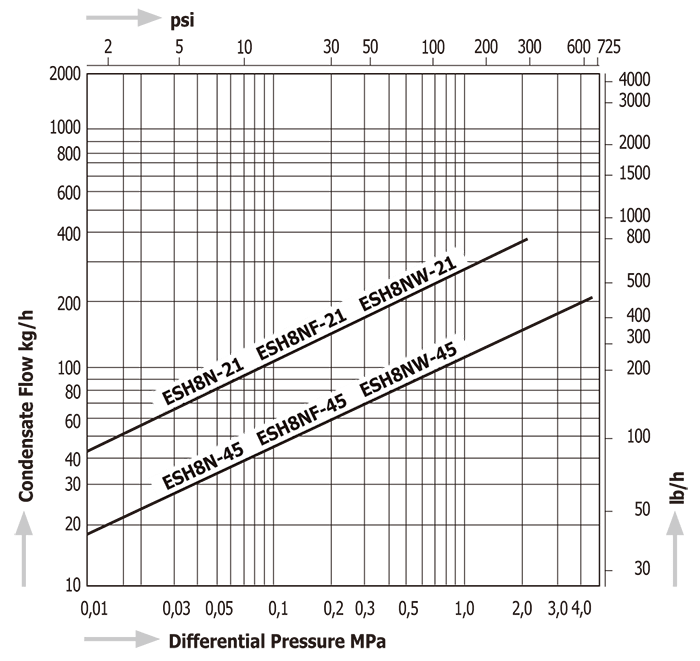

- Wide Pressure Range: The ESH8N operates effectively across a broad range of pressures, making it suitable for many industrial processes.

- Leak Prevention: Precision engineering means reliable seating and minimal risk of leaks, protecting machinery and preventing unnecessary energy waste.

The Inverted bucket steam trap - ESH8N | Miyawaki is the smart choice for industries that demand performance and dependability. Its clever design eliminates the hassle of manual condensate removal and helps maintain optimal steam quality—keeping your production line moving and your maintenance costs low. Choose Miyawaki ESH8N for a solution that combines robust engineering with real-world practicality.