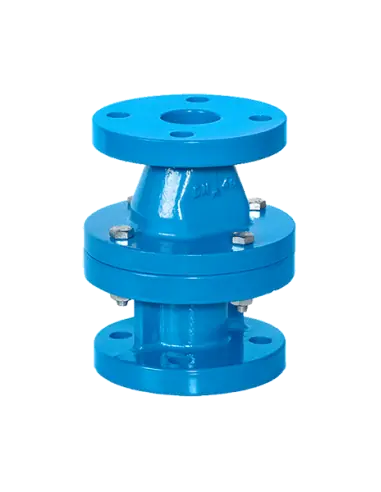

Swing Check Valve - T114AR | Zubi: Reliable Flow Control for Industrial Demands

The Swing Check Valve - T114AR | Zubi is expertly engineered to provide dependable, one-way flow control for a wide range of industrial applications. Crafted with durability and performance in mind, this swing check valve delivers peace of mind and long-lasting efficiency in every operation.

Key Features & Benefits of the Swing Check Valve - T114AR | Zubi

- Automatic Backflow Prevention: The swing mechanism ensures that liquid or gas flows in just one direction, automatically closing if flow reverses. Protect pipelines and equipment from potential damage without manual intervention.

- Robust Construction: Built with top-quality materials, this valve resists corrosion, pressure, and harsh working conditions. It’s designed for lasting reliability in industrial settings.

- Minimal Maintenance: The simple design means fewer moving parts, reducing the need for regular maintenance and lowering overall operating costs.

- Effortless Installation: The user-friendly structure allows for straightforward installation, saving valuable time during system setup or replacement tasks.

- Low Pressure Drop: The streamlined design ensures smooth flow with minimal pressure loss, keeping your system efficient and energy costs down.

- Versatile Application: Ideal for sectors like water treatment, chemical processing, and various industrial pipelines that require reliable backflow prevention.

With the Swing Check Valve - T114AR | Zubi, you ensure optimal protection for your processes and machinery. The valve’s advanced swing design keeps operations running smoothly, even under changing flow conditions. Its sturdy build offers consistent performance, meaning fewer interruptions and greater productivity for your business.

Whether managing large-scale industrial systems or enhancing routine plant operations, this swing check valve stands out as a smart, cost-effective solution. Equip your facility with the confidence that only proven technology and thoughtful engineering can bring.