ARI-SAFE Safety Valve Features:

- Type: Full lift safety valve (D/G) and standard safety valve (F).

- Approvals: Type-test approved according to DIN EN ISO 4126-1, AD2000-A2, TRD 421, and more, with TÜV certifications.

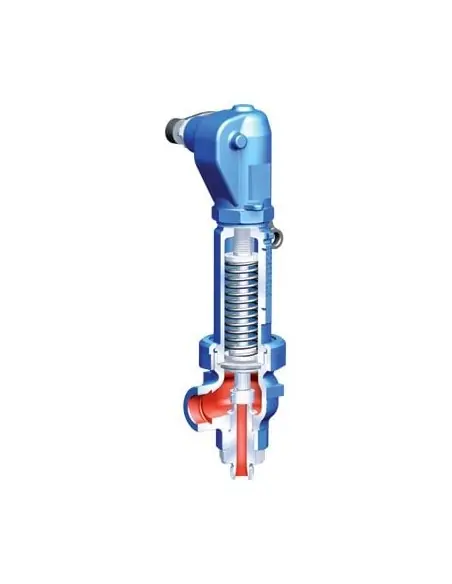

- Design:

- Spring-loaded, direct-loaded safety valve.

- Wear-resistant seat/disc for enhanced longevity.

- Precision alignment of the disc and guide for smooth operation.

- Soft seal disc and options for EPDM or stainless steel bellows.

- Common thread types available for various applications.

Technical Specifications:

- Nominal Pressure:

- Available in PN16, PN25, PN40, and other ratings depending on the material and model.

- Material:

- Various materials such as EN-JL1040, EN-JS1049, 1.0619+N, and 1.4408 (stainless steel).

- X6CrNiMoTi17-12-2, 1.4571 for high-durability components like the seat and spindle guide.

- Temperature Range: From -60°C to +450°C, depending on the material used.

- Flange Connection: Standard DIN EN 1092-1 for various pressure classes.

Sizing and Application:

- Capacity: The valve's capacity depends on the medium (steam, air, water) and the set pressure.

- Medium Details: Calculations are based on the mass flow, molar mass, temperature, set pressure, and back pressure.

- Back Pressure: Can be superimposed (no back pressure allowed on request) or built-up (max. 10% from set pressure, higher on request).

Valve Sizes:

- Nominal Diameters (DN): Available from DN15 up to DN350, depending on the application.

- Spring Range: The valves are available in various spring ranges for different pressures, from 0.2 bar to 40 bar.

Additional Features:

- Lift Fork and Levers for operation.

- Bellows (optional) for sealing at high pressures.

- Balanced piston for some models.

- Sealing Rings: Pure graphite or CuFA materials for better sealing.

Applications:

- These valves are used in steam, air, and water systems and are ideal for pressure regulation in industrial systems.

- They are critical in maintaining safe operating pressures and preventing overpressure scenarios.