Inverted bucket steam trap - ER105 | Miyawaki: Reliable Performance & Smart Engineering

The Inverted bucket steam trap - ER105 | Miyawaki is designed to bring efficiency and durability to your industrial steam systems. Built for demanding environments, this device ensures uninterrupted flow and helps you get the most out of your equipment. Easy to install and simple to maintain, the ER105 makes steam management straightforward for any user.

Features & Benefits of the Inverted bucket steam trap - ER105 | Miyawaki

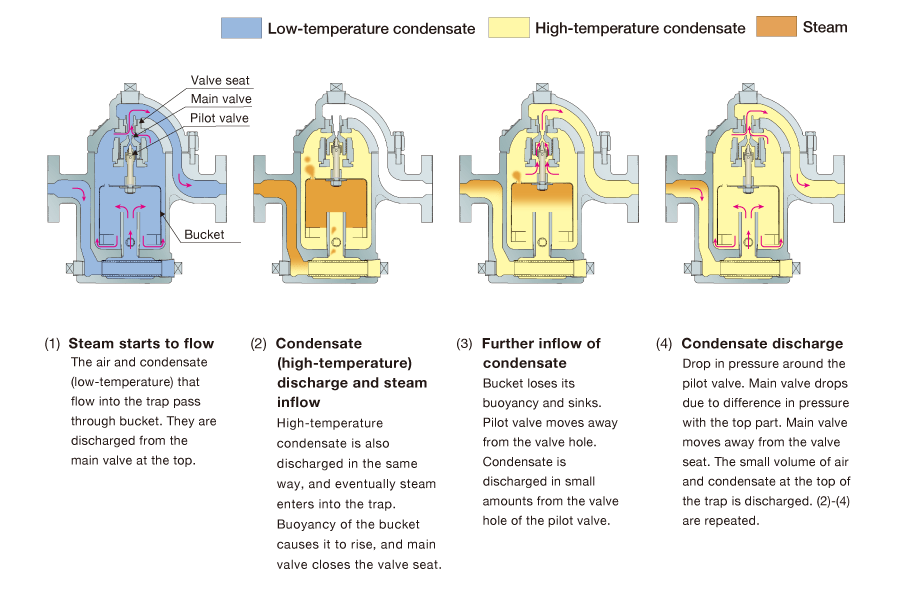

- Consistent Steam Flow: Its advanced inverted bucket mechanism allows only condensate and non-condensable gases to escape, making sure that valuable steam stays within your system and out of your waste lines.

- Robust Construction: Made with high-quality materials, the ER105 is engineered to withstand high pressures and extreme conditions, offering reliable long-term service even in the toughest industrial settings.

- Easy Maintenance: With its simple design, checking and replacing parts is quick and hassle-free, saving valuable time and reducing downtime in your process line.

- Energy Savings: Efficient steam trapping means your system uses less energy. The ER105 helps lower fuel costs by preventing steam loss, making your plant more economical and environmentally friendly.

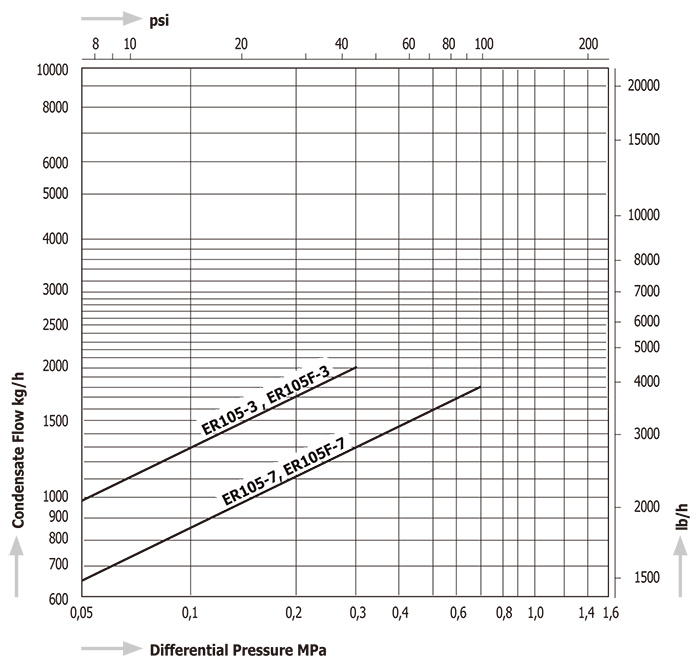

- Wide Operating Range: The ER105 can handle a range of pressures and temperatures, making it versatile for different applications within your industrial plant.

This steam trap works by using an inverted bucket that floats up and down as condensate enters. As it fills, the bucket sinks, opening the valve to release the condensate. When steam enters, the bucket rises, closing the valve and keeping steam inside the system. This clever design means the ER105 works automatically without the need for manual adjustments or complicated controls.

With the Inverted bucket steam trap - ER105 | Miyawaki, you get peace of mind knowing your equipment is protected from water hammer and corrosion caused by unwanted condensation. The result? Reduced maintenance costs, smoother operation, and a longer lifespan for your entire steam system.

Choose the ER105 for your facility and experience the difference in efficiency, dependability, and ease of use. It’s the ideal solution to help your plant run smoother and smarter, every day.