Inverted bucket steam trap - ER110 | Miyawaki: Reliable Performance, Smart Engineering

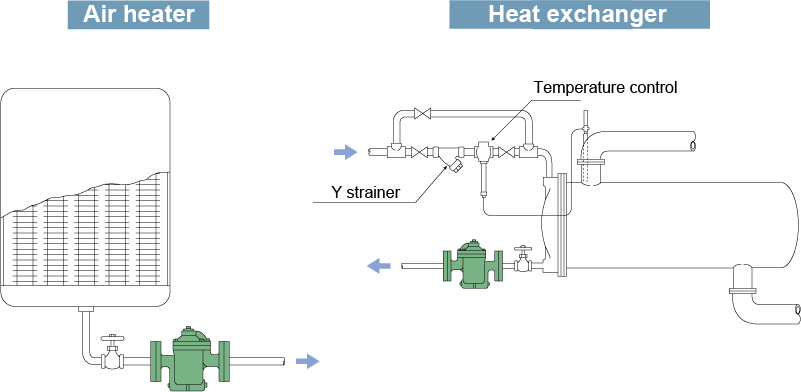

Discover the efficiency and dependability of the Inverted bucket steam trap - ER110 | Miyawaki, engineered for seamless steam system operation in industrial settings. This innovative device is designed to remove condensate while blocking steam loss, ensuring your system runs smoothly and cost-effectively.

Main Features and Benefits of the Inverted bucket steam trap - ER110 | Miyawaki

- Durable Construction: Built with top-quality materials, the ER110 withstands demanding industrial environments, offering a long service life and reducing the need for frequent replacements.

- Consistent Operation: The inverted bucket mechanism ensures that only condensate is discharged, keeping valuable steam inside your system and maximizing energy savings.

- Easy Maintenance: A simple design makes inspection and upkeep straightforward, minimizing downtime and maintenance costs.

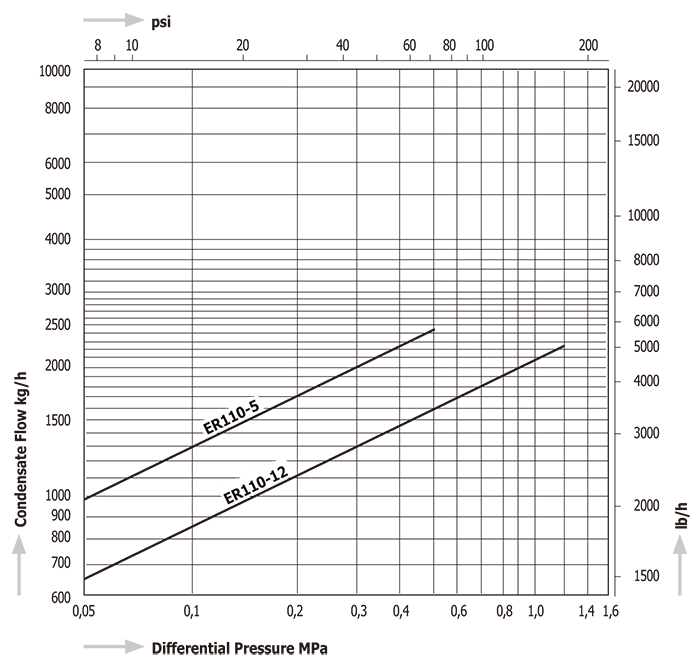

- Wide Compatibility: Suitable for a variety of pressures and temperatures, this steam trap adapts effortlessly to your existing setup.

- Effective Air Discharge: Automatically removes air from your system, helping start-ups run faster and improving overall efficiency.

The Inverted bucket steam trap - ER110 | Miyawaki offers peace of mind by maintaining optimal performance without constant monitoring. Its advanced design keeps your steam system protected from damaging water hammer and corrosion, which can lead to costly repairs and downtime.

Unlike other steam traps, the ER110’s inverted bucket principle relies on a simple but highly effective float mechanism. This allows it to handle dirt and condensate with ease, making it the ideal choice for installations where reliability is essential. The robust body ensures resistance to wear, even in the harshest industrial conditions.

Energy efficiency is at the heart of the ER110, helping you save money on fuel and reducing energy waste by preventing steam loss. With dependable air venting, processes start and run faster, boosting productivity and ensuring that machinery operates at its best.

Upgrade your facility’s performance with the Inverted bucket steam trap - ER110 | Miyawaki—a smart investment for any industrial steam application seeking safety, efficiency, and lasting value.