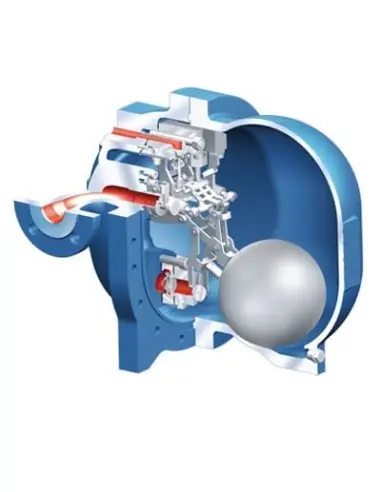

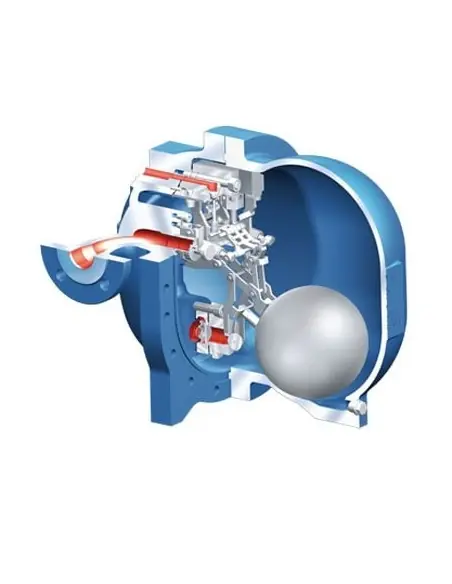

ARI-CONA P® Float-operated Pump Trap Features:

- Automatic Operation: The pump trap adapts automatically to the condensate level and pressure conditions without requiring manual settings.

- Design: The pump trap is robust and durable with all internals made of stainless steel and wear parts made of hardened stainless steel. It includes Inconel X-750 springs for high endurance.

- No Leakage: Since there are no moving exterior parts, the trap operates without leakage.

- Energy Efficient: It works without electricity and can adapt to different pressure conditions, making it suitable for various applications.

- Low Filling Head: It requires a minimal filling head for operation.

- Connections: Available with screwed sockets, loose flanges, or union with butt weld ends as options.

Specifications:

- Operating Pressure:

- Minimum: -0.8 barg

- Maximum: 8/13 barg depending on the configuration.

- Operating Temperature: From -10°C to 200°C.

- Fluid Group: Suitable for group 2 fluids with a density of 0.85 to 1.15 kg/dm³.

Connection Types:

- Screwed sockets: For condensate inlet and outlet (Rp 1 1/2"), motive medium (Rp 1/2"), and air vent (Rp 3/4").

- Loose flange (optional): For condensate inlet and outlet, similar to EN 1092-1.

- Union with butt weld ends (optional): Available for DN25, DN40, DN50 for condensate inlet, outlet, motive medium, and air vent.

Capacity and Flow:

- The volume displacement is 10.5 liters.

- The vessel volume is around 22 liters.

Installation:

- The standard installation is horizontal, but the pump can operate effectively in other orientations as well.

- The required filling head above the pump trap footprint is 300 mm minimum, with the recommended range being between 500 mm to 1200 mm.

Applications:

- Condensate Recovery: This pump trap is used to recover condensate from heat exchangers and vessels under varying pressure conditions.

- Automatic Mode Switching: The pump trap can operate as a normal steam trap when the pressure difference is positive and switch to a condensate pump when the pressure difference is negative.

Additional Information:

- The maximum test pressure for shell strength and seat tightness tests is 32 bar at room temperature.