Most used standard of reference are API 6D, regular opening, API 594, BS 1868. EN and ISO standard can also be referred to.

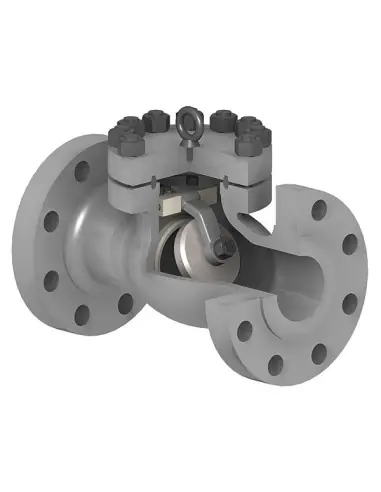

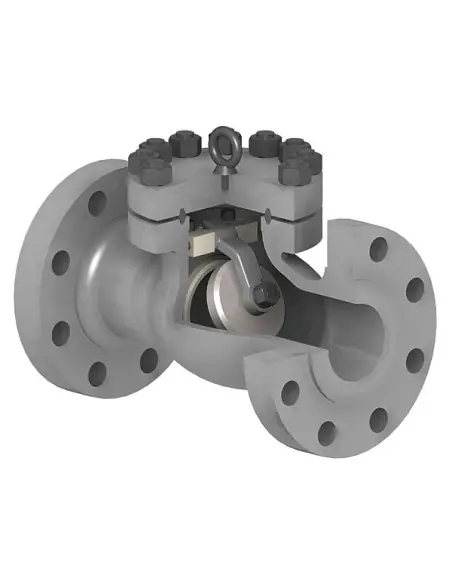

Constructions with internal hinge pin are available, together with the more traditional construction with hinge pin inserted from the side. The latter allows application of optional requests, such as position indicator (with or without limit switches), locking systems in the open position (to exclude the unidirectional non return function), anti-slam external counter weights. A rotary anti-slam system applied to the external part of the hinge pin is also available (industry calls it “dash pot system”).

Materials available include carbon steel, low temperature carbon steel, low alloy steel, austenitic stainless steels, austenitic-ferritic duplex stainless steel, nickel alloys. ANSI classes normally available are 150#, 300# and 600#.