ARI-Strainer Models:

-

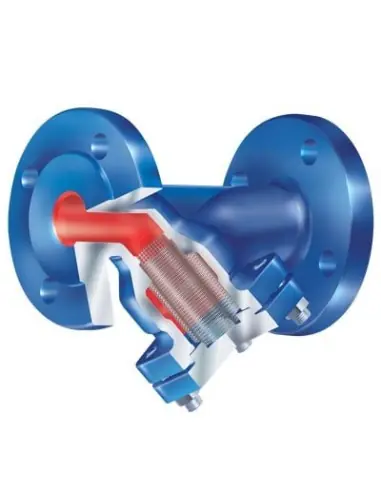

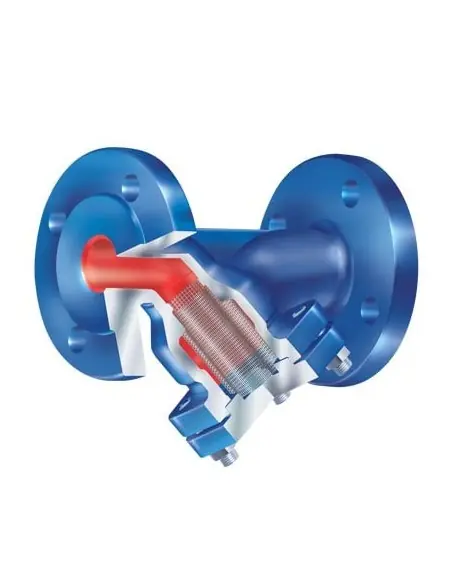

Y-Pattern with Flanges:

- Materials: Grey Cast Iron, SG Iron, Cast Steel, and Stainless Steel.

- Available sizes: DN15-DN200 for Grey Cast Iron, DN15-DN200 for Stainless Steel.

- Features: Screen and supporting basket made of stainless steel.

- Options for different mesh widths for standard and fine screens.

-

Straight Through with Flanges:

- Materials: SG Iron, Cast Steel.

- Available sizes: DN250-DN500.

- The screen and supporting basket are also made of stainless steel.

- Mesh widths: 1 mm, 1.25 mm, 1.6 mm for standard screens and 0.25 mm, 0.8 mm for fine screens.

-

Y-Pattern with Butt Weld Ends:

- Materials: Cast Steel.

- Available sizes: DN15-DN300.

- Features: Stainless steel screen and supporting basket.

- Suitable for applications with higher differential pressures, especially with larger diameters.

Technical Data:

- Kvs-values: Vary depending on the nominal diameter, with Kvs-values ranging from 6.9 m³/h for smaller sizes to 1873 m³/h for larger sizes.

- Zeta-values: Vary depending on mesh width and size, with Zeta-values ranging from 1.7 to 8.6 for different models.

- Dimensions: The face-to-face dimension varies by size and model, with dimensions for different DN values provided (e.g., DN15-DN200 ranges from L=130mm to 480mm).

Pressure and Temperature Ratings:

- PN6, PN16, PN25, and PN40 ratings are available, with the maximum temperature for various materials ranging up to 450°C.

- The valves are compliant with EN ISO 15848-1 / TA - Luft and have a TÜV-Test certificate (Test-No. TA 09 2016 C04).

Applications:

- Used in a variety of industries to protect systems from debris and particles by filtering out unwanted materials. These strainers are commonly used in applications requiring high flow rates and can be used in systems involving steam, water, or chemicals.

Additional Features:

- The strainers are designed to provide precise guidance of the screen in both the cover and the body to maintain effective filtration.

- A supporting basket is necessary for higher differential pressures, particularly for sizes DN>125.