General Features:

- Automatic valve travel or rotation angle adaption.

- Wear-free, contactless position sensing via a magnetic Hall sensor.

- Low air consumption.

- Simple and clear parameterization using handy switches.

- Operation: 4 - 20 mA.

- Optional feedback signal: 4 - 20 mA.

- Manometer: Optional for pressure indication.

- Pressure Venting: Valve is vented in case of signal or air pressure failure.

Functional Description:

- The ARI-STEVI-POS® positioner is designed to convert a 4-20 mA electrical signal into a valve position for single-acting pneumatic actuators.

- The positioner detects the actual position using a contactless, wear-free Hall sensor and compares it to the setpoint.

- The pneumatic module adjusts the pressure in the actuator to match the setpoint within a defined deadband range.

- Deadband: Can be set automatically or manually to values such as 0.5%, 1%, or 3%.

- Tight-closing function: The actuator is completely vented to maximize force for closing when the setpoint goes below or above adjusted limits. This function can be switched on/off as needed.

Technical Data:

- Stroke Range (linear actuator): From 10 mm to 120 mm.

- Rotation Angle (rotary actuator): From **25° to 100°.

- Pneumatic Supply: 1.4 to 7 bar (20 to 105 psi).

- Pneumatic Air Connection: G1/4.

- Air Consumption: ≤ 0.024 m³/h (at 25°C).

- Maximum Cable Cross Section: 2.5 mm².

- Cable Diameter for Cable Glands: Ø8 - 13 mm.

- Linearity: ±1.5% F.S..

- Hysteresis: 1.4% F.S..

- Resolution: 0.5% F.S..

- Protection Class: IP66 (dust and water protection).

- Ambient Temperature: -20°C to +80°C.

- Body Material: PA (Polyamide).

- Hood Material: PC (Polycarbonate).

Behavior in Failure Modes:

- Control signal failure: Valve is vented.

- Air pressure failure: Valve is vented.

Accessories:

- NPT Air Connection (optional): 1/4-18 NPT (with NPT Adapter).

- Manometer: Two pieces, 0-10 bar (0-140 psi) for supply air and working pressure.

- Analog Output Card: 4-20 mA passive for current loop (9-32 V).

Mounting:

- Can be mounted in any position, with the exception of air connections and silencers not being oriented upwards.

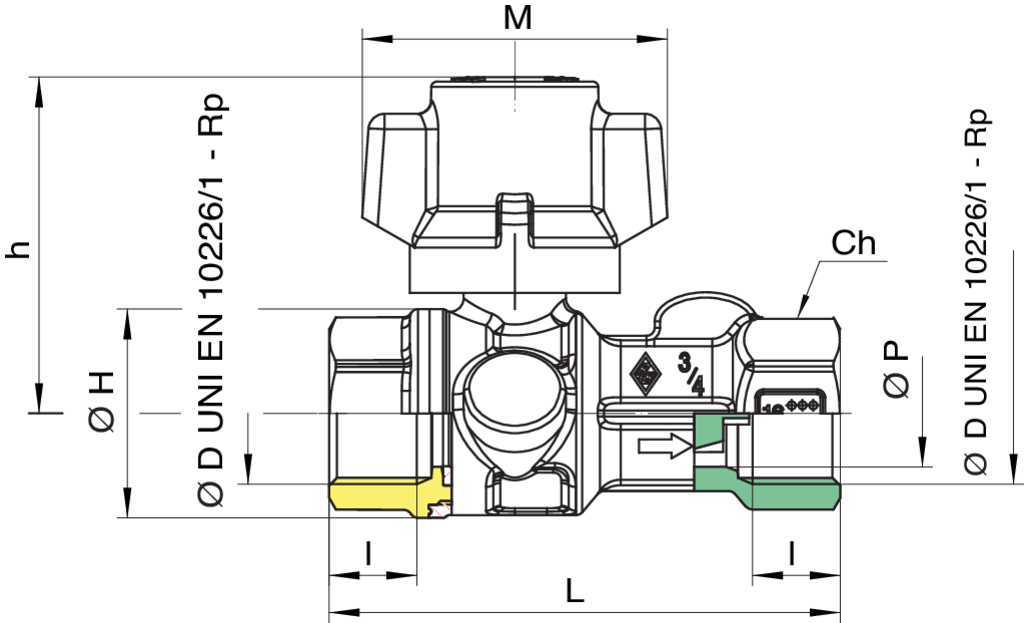

Dimensions:

- Linear Actuators: Dimensions for installation and mounting on linear actuators are provided.

- Rotary Actuators: Dimensions for rotary actuators are provided as well.