Key Features of CODI®S and CODI®B:

- CODI®S (PN40) with gland packing and CODI®B (PN40 / PN63) with bellows seal for maintenance-free operation.

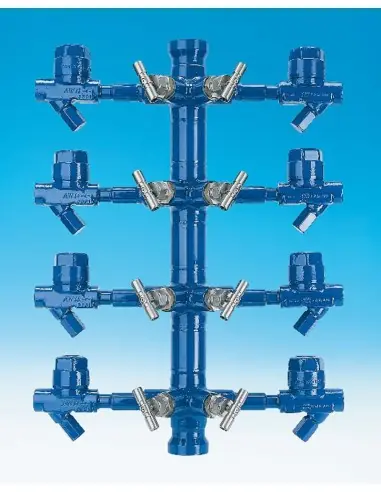

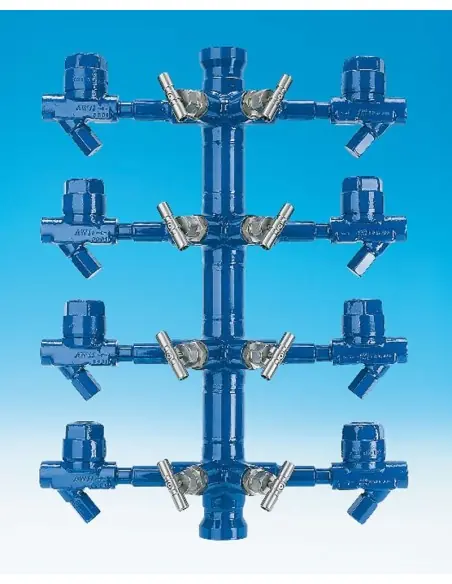

- Modular design for flexibility, available with 2, 4, 6, 8, 10, 12, 14, 16, or 18 integrated stop valves.

- Primary connections available in flanges, screwed sockets, socket weld ends, and butt weld ends.

- Secondary connections with options for various pipe sizes and ANSI versions.

- Stop valves with open-close or throttling functions.

- Safety back seat when the valve is fully opened to prevent leakage.

Pressure and Temperature Ratings:

- CODI®S (PN40): Operating pressure up to 32 barg and inlet temperature up to 250°C (or 400°C for some models).

- CODI®B (PN40 / PN63): Operating pressure up to 45 barg and inlet temperature up to 350°C (for PN63).

Models & Materials:

- CODI®S (PN40): Available in Forged Steel (P250GH, 1.0460) and Stainless Steel (1.4541).

- CODI®B (PN40 / PN63): Available in Forged Steel (P250GH, 1.0460) and Stainless Steel (1.4541).

Types of Connections:

- Primary connections: Flanges, socket weld ends, butt weld ends, screwed sockets (Rp or NPT).

- Secondary connections: Customizable as per the required installation.

Applications:

- Condensate collection and steam distribution for industrial systems such as chemical processing, HVAC, and water treatment systems.

- The steam inlet is at the top flange, with the condensate outlet generally at the bottom flange.

Installation and Options:

- The valves can be mounted vertically (preferred) or horizontally.

- Optional insulating jackets for energy saving and protection against heat loss.

- Additional options include immersion tubes, fastening parts, and mounting wrenches.