Inverted bucket steam trap - ER116 | Miyawaki: Reliable Steam Management for Industrial Needs

The Inverted bucket steam trap - ER116 | Miyawaki brings robust performance and trusted efficiency to your steam system. Designed for demanding industrial environments, this steam trap excels in removing unwanted condensate while minimizing steam loss, keeping your operations smooth and energy costs in check. Its simple yet smart design ensures effective separation of steam and condensate, making it a practical choice for a wide range of applications.

Features & Benefits of the Inverted bucket steam trap - ER116 | Miyawaki

- Durable Construction: Built with tough materials, this trap can withstand high-pressure steam and harsh conditions, ensuring long-lasting performance.

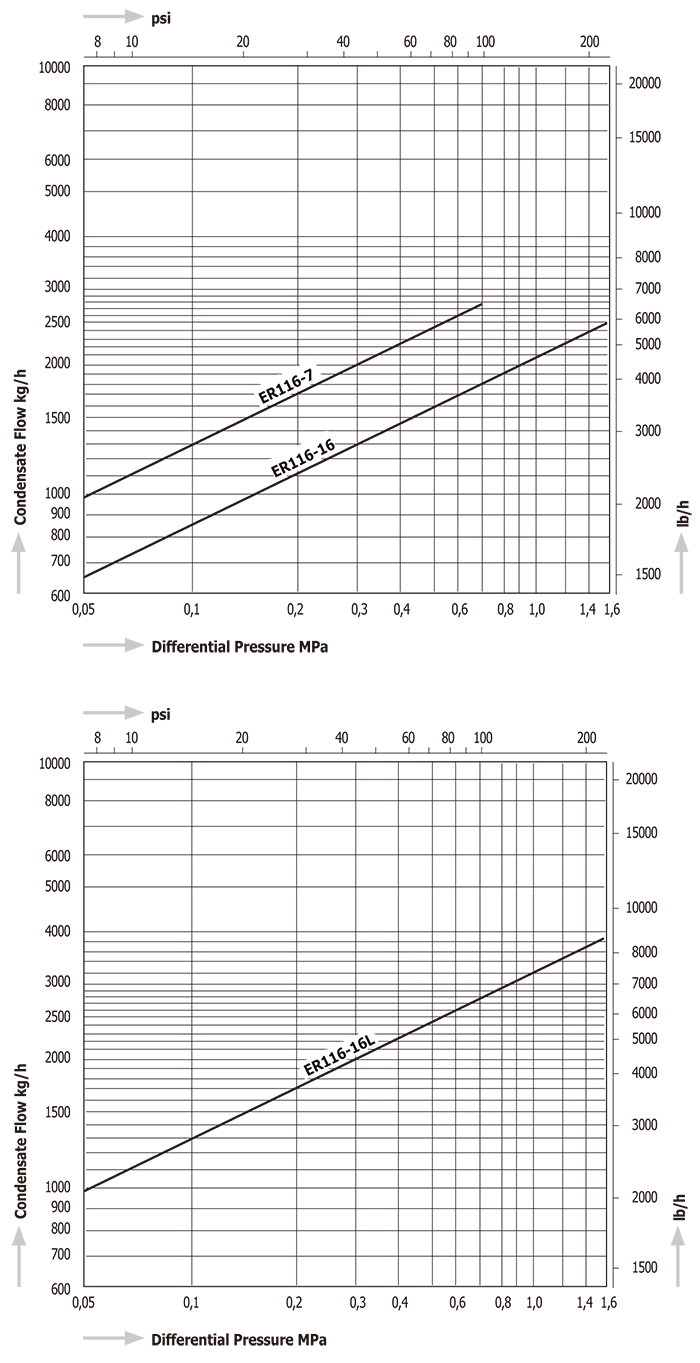

- Efficient Condensate Removal: The inverted bucket design opens and closes precisely, allowing fast discharge of condensate while holding back valuable steam.

- Low Maintenance: With fewer moving parts and a self-cleaning mechanism, maintenance is minimal. This means less downtime and more time focused on your core work.

- Energy Savings: By preventing steam loss, the ER116 helps you save on energy bills and improves the overall efficiency of your steam system.

- Reliable Operation: The simple mechanism works consistently, resisting water hammer and corrosion, making it perfect for continuous industrial use.

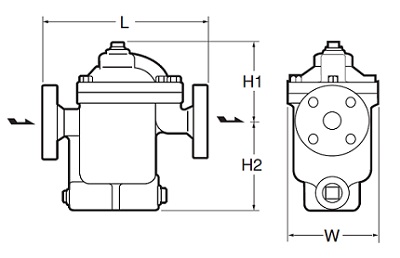

- Easy Installation: Compact and lightweight, installation is straightforward. It fits into most existing systems without the need for complex adjustments.

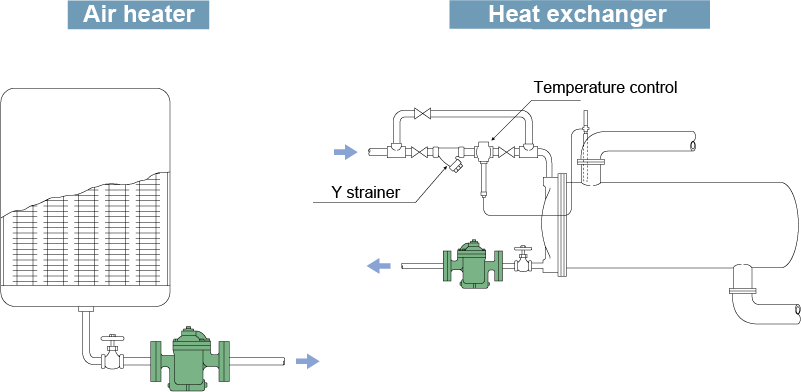

- Versatile Application: Suitable for a range of industrial setups, including process equipment, steam pipelines, and heat exchangers.

Advanced features like the self-acting valve and rugged body mean the Inverted bucket steam trap - ER116 | Miyawaki can handle fluctuating pressures and varying loads without missing a beat. Its design not only ensures top performance but also protects your equipment from water buildup and potential damage, extending the life of your system.

Choose the Inverted bucket steam trap - ER116 | Miyawaki for dependable, efficient, and easy-to-use steam management—essential for any modern industrial setting. It’s the smart investment for businesses that value reliability and cost control.