Efficient Fluid Purification with Separators Type AS 2 | Mankenberg

Experience flawless fluid management in your industrial applications with the Separators Type AS 2 | Mankenberg. This advanced separator is designed to deliver outstanding performance, ensuring that your piping systems remain free from unwanted particles and contaminants. With its robust construction and smart engineering, it is the perfect solution for achieving cleaner, more reliable operations.

Key Features & Benefits of Separators Type AS 2 | Mankenberg

- High-Efficiency Separation: The AS 2 separator removes foreign particles and moisture from steam, air, or gases, improving the quality of your process fluids and protecting your equipment from damage.

- Durable Stainless Steel Design: Built to last in tough industrial environments, the stainless steel body ensures long service life and resistance to corrosion and wear.

- Easy Installation: Compact and lightweight, the AS 2 is simple to integrate into existing piping systems without the need for specialized tools or extensive modifications.

- Low Maintenance: With fewer moving parts and a self-cleaning construction, routine maintenance is minimal, reducing downtime and ongoing operational costs.

- Versatile Use: Suitable for various industries such as chemical, food processing, and pharmaceutical sectors, the AS 2 handles a wide range of fluids with different temperatures and pressures.

- Reliable Performance: Proven engineering ensures stable operation even under fluctuating load conditions, delivering consistent purification day after day.

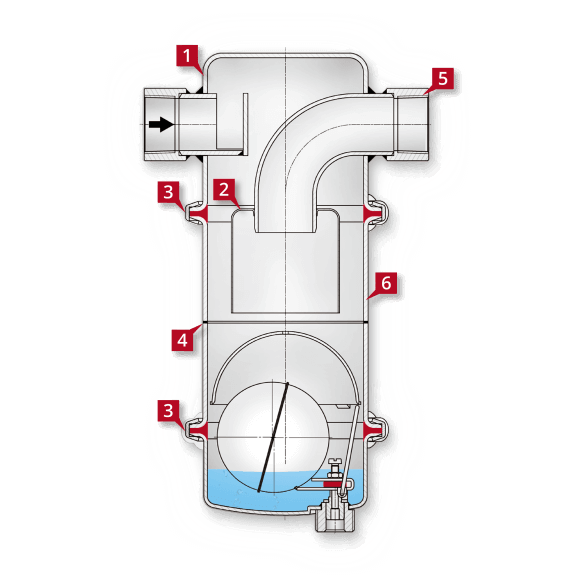

The Separators Type AS 2 | Mankenberg works by directing the flow along a special path that forces heavier droplets and particles to separate from the fluid stream. This keeps your pipes, valves, and downstream equipment safe from blockages and wear.

Energy savings come naturally, as the AS 2’s smooth-flow design minimizes pressure loss. This means your system operates efficiently, with less strain on pumps and compressors. The clever design ensures that only clean, dry fluids continue on their journey through your plant, boosting end-product quality while reducing the risk of costly repairs.

Designed for easy inspection, the separator gives you peace of mind when it comes to maintenance. It can be quickly checked and cleaned, ensuring your processes run smoothly. The flexible mounting options make it adaptable to many different system layouts, so you spend less time worrying about compatibility.

Choose Separators Type AS 2 | Mankenberg for a trusted, easy-to-use, and cost-effective solution to fluid purification. Empower your industrial processes with cleaner fluids, longer equipment life, and the reliability you need to stay ahead.