Rubber Lined Dual Plate & Ball Check Valve | Cast Flow – Advanced Solutions for Industrial Fluid Control

Experience reliability and efficiency with the Rubber Lined Dual Plate & Ball Check Valve | Cast Flow, engineered to provide high-level protection and smooth operation in challenging industrial environments. Designed for industries where flow control, durability, and low maintenance are essential, this valve brings a smart solution to fluid management systems.

Features & Benefits – Why Choose the Rubber Lined Dual Plate & Ball Check Valve | Cast Flow?

- Superior Corrosion Resistance: The rubber lining ensures lasting protection against harsh chemicals and abrasive fluids, extending the valve’s lifespan and reducing maintenance needs.

- Efficient Flow Control: Dual plate design enables fast response to changes in flow direction, preventing reverse flow and safeguarding pumps and piping systems.

- Minimized Water Hammer: Ball check mechanism absorbs sudden pressure changes, protecting your equipment from shocks and noise.

- Low Operating Costs: Maintenance-free construction means less downtime and fewer repairs, saving time and resources for your operations.

- Simple Installation: Lightweight, compact build allows easy handling and fitting, even in tight spaces.

- Wide Compatibility: Suitable for a range of industrial fluids, from water to aggressive chemicals, making it a flexible option for different systems.

The Rubber Lined Dual Plate & Ball Check Valve | Cast Flow is crafted with robust materials and a tough rubber lining, combining strength with chemical resistance. Its dual plate mechanism responds instantly to prevent backflow, while the ball check system cushions pressure spikes, delivering consistent performance every time.

Ideal for applications in chemical plants, water treatment, and other demanding industrial environments, this valve offers dependable protection for your pumps and pipelines. Easy to install and even easier to maintain, it’s the smart choice for operators who value efficiency and peace of mind.

Upgrade your flow control with the Rubber Lined Dual Plate & Ball Check Valve | Cast Flow – the partner your industrial system deserves for safe, reliable, and long-lasting performance.

Description

Certificates

CHECK VALVES MANUFACTURER

WATER TECHNOLOGIES – IN HOUSE MANUFACTURING

CASTFLOW VALVES S.L., is formed by technicians that have been developing valves for many years.

Counting on this experience we created new patterns for castings, including the improvements that

have been necessary to obtain a longer durability and better hydraulic features.

CASTFLOW VALVES S.L. is a ISO 9001:2015

ISO 14001:2015 – ANNEX III MODULE H approved company for design and production.

We produce valves based on our own design and we can offer to our clients all

TECHNICAL SUPPORT related to our valves.

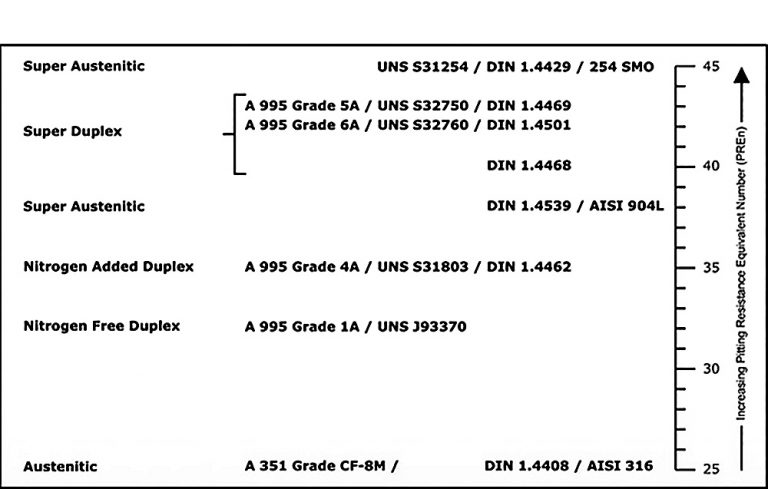

We require maximum quality on prime materials. The foundries we work with, are highly specialised in

materials and posses a very important knowledge in casting our products. Our department for investigation and development is orientated to the technical requests of

our customers, adapting our development to these requests. The structure of CASTFLOW VALVES S.L.is oriented to serve our customers technical requests.

ISO 9001:2015

ISO 14001:2015

ANNEX III MODULE H

- CERTIFICATE OF THE QUALITY ASSURANCE SYSTEM EUROPEAN DIRECTIVE 2014/68/EU

- ISO 14001:2015

- ISO 9001:2015

Quality assurance plans

PROVIDING HIGH QUALITY PRODUCTS

Based on the customers requirements CASTFLOW VALVES S.L. can proceed with testing methods

according to a quality assurance plan and test and inspection schedules.

Receiving inspection

In process Control

Non destructive testing

US-testing-magetic

particle-dye

penetrant tests Porotest Dk30

Output control

pressure test of each valve

output documents

termination control

marking and packaging control