Strainer Division - Y Cast | Conaco: The Smart Choice for Industrial Filtration

Experience reliable performance and superior filtration with the Strainer Division - Y Cast | Conaco. Designed for industrial environments, this robust strainer ensures your systems operate efficiently while keeping them protected from unwanted particles and debris. Ideal for pipelines and processing plants, it’s the essential solution for smooth, uninterrupted operation.

Features & Benefits: Why Choose Strainer Division - Y Cast | Conaco?

- Outstanding Filtration: Effectively traps dirt, rust, and other solids, keeping your equipment running clean and safe from clogs and wear.

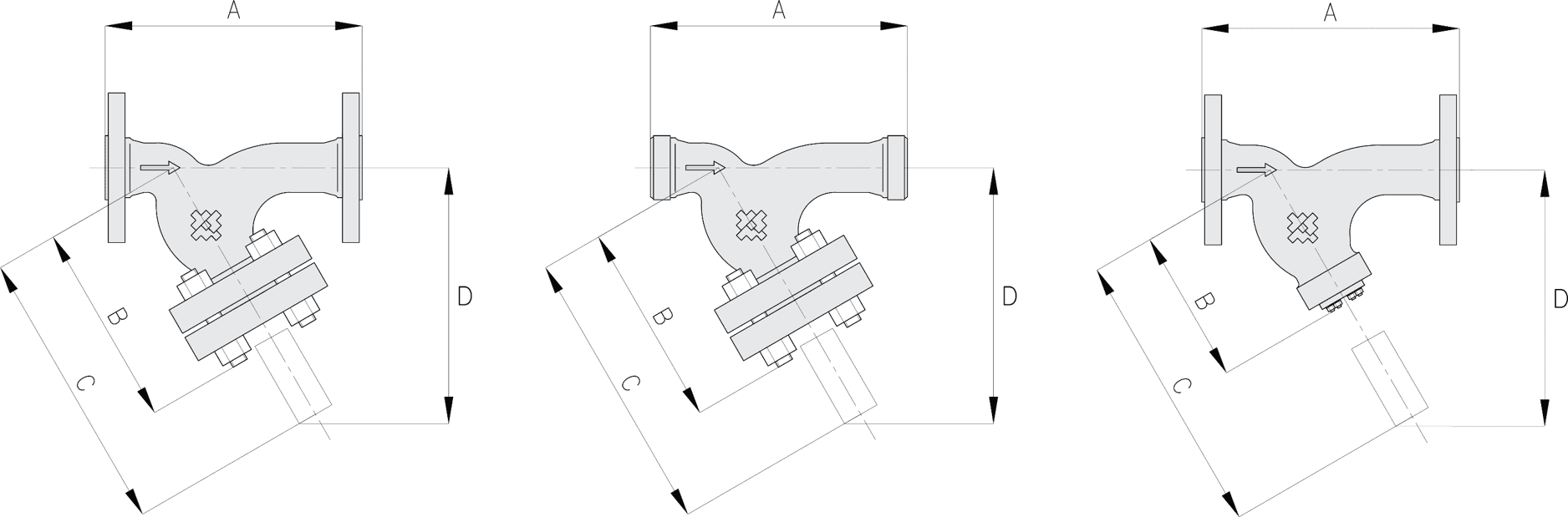

- Durable Y-Shaped Design: The smart Y configuration allows liquid to flow freely while capturing sediments in a dedicated chamber, making cleaning quick and simple.

- Heavy-Duty Casting: Manufactured with premium cast materials for maximum strength, this strainer stands up to tough industrial workloads and resists corrosion.

- Easy Maintenance: A removable cover makes inspection and cleaning hassle-free, reducing downtime and keeping productivity high.

- Seamless Installation: With standard connection sizes and a compact body, it fits easily into your piping system without complicated setup.

- Reliable Protection: By removing unwanted particles, it extends the life of pumps, valves, and other sensitive equipment, leading to fewer repairs and lower maintenance costs.

Designed for the demands of industrial use, the Strainer Division - Y Cast | Conaco is your go-to choice for problem-free operation. Its sturdy construction and simple, practical features mean less stress and more efficiency for your facility. Whether handling water, chemicals, or other fluids, this strainer delivers consistent results and protects your entire system from costly damage.

Choose the Strainer Division - Y Cast | Conaco for a filtration solution you can trust—built for performance, designed for easy use, and made to keep your operations running smoothly day after day.