Μειωτής Πίεσης Αμέσου Δράσεως Miyawaki τύπος RE1 – Ισχυρή λύση για σταθερή και ασφαλή πίεση

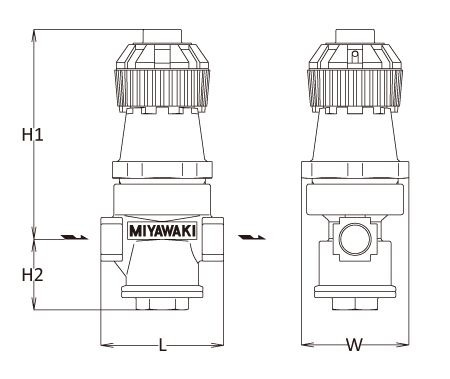

Ο Μειωτής Πίεσης Αμέσου Δράσεως Miyawaki τύπος RE1 αποτελεί κορυφαία επιλογή για βιομηχανικές εφαρμογές που απαιτούν ακρίβεια και αξιοπιστία στη ρύθμιση της πίεσης. Σχεδιασμένος με σύγχρονη τεχνολογία, προσφέρει άμεση και αποτελεσματική μείωση της πίεσης, βοηθώντας στη σταθερότητα και την αποτελεσματικότητα των συστημάτων σας.

Χαρακτηριστικά & Οφέλη του Μειωτή Πίεσης Αμέσου Δράσεως Miyawaki τύπος RE1

- Άμεση Αντίδραση: Ρυθμίζει την πίεση χωρίς καθυστερήσεις, προσφέροντας συνεχή προστασία στον εξοπλισμό σας.

- Εύκολη Εγκατάσταση: Ο εργονομικός σχεδιασμός του επιτρέπει γρήγορη τοποθέτηση σε όλα τα στάδια της βιομηχανικής γραμμής.

- Αντοχή σε Δύσκολες Συνθήκες: Κατασκευασμένος από υλικά υψηλής ποιότητας, αντέχει στη σκληρή χρήση και διασφαλίζει μακροζωία.

- Ασφάλεια για τον Εξοπλισμό: Προστατεύει τις εγκαταστάσεις από υπερβολικές πιέσεις, μειώνοντας τον κίνδυνο φθοράς ή βλάβης.

- Ευκολία στη Ρύθμιση: Με πρακτικό σύστημα ρύθμισης, η αλλαγή στις απαιτούμενες τιμές πίεσης γίνεται απλά και γρήγορα.

Ιδανικός για εργοστάσια, βιοτεχνίες και κάθε είδους βιομηχανική χρήση, ο Μειωτής Πίεσης Αμέσου Δράσεως Miyawaki τύπος RE1 βελτιώνει την απόδοση και προστατεύει το δίκτυό σας. Απολαύστε σιγουριά στη λειτουργία των μηχανημάτων σας και εξοικονομήστε χρόνο από απρόοπτα προβλήματα που σχετίζονται με την πίεση.

Επιλέγοντας τον Μειωτή Πίεσης Αμέσου Δράσεως Miyawaki τύπος RE1, εξασφαλίζετε σταθερότητα, ασφάλεια και λειτουργικότητα. Κάντε το σύστημα σας πιο αποδοτικό και ανθεκτικό με τη σίγουρη λύση που εμπιστεύονται τα μεγαλύτερα εργοστάσια.