FLUITEK ORSENIGO VALVES has a very extended experience in manufacturing this type of valve. It’s the most well known on-off valve for high pressure applications.

It’s features:

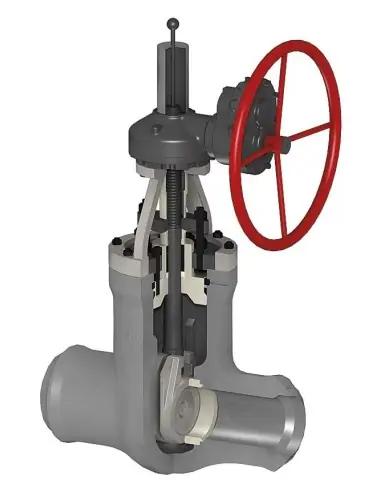

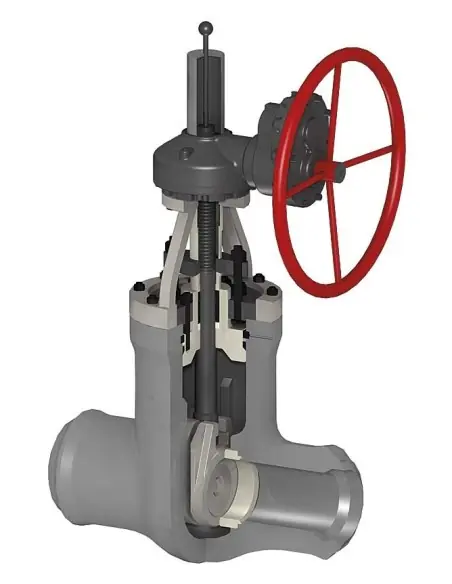

- flex wedge disc

- pressure seal body/bonnet joint (also called autoclave)

- high strength construction

are deemed to obtain optimum and safe functioning at medium to high pressures. The pressure seal body/bonnet joint uses a composite graphite/stainless steel seal ring that is today’s optimum solution sealing mechanism. Bi-directional on-off functioning is guaranteed with both seats being tested. Operation, depending on size, pressure class and customer demand can be manual with handwheel, manual with gear operator, electric motor actuated, pneumatic operated.

Design can be to ASME B16.34 as well as to EN 12516. Cast body construction (both flanged and with butt weld ends) and forged body construction (with butt weld ends) are both available.

Materials range from carbon steel to low alloy steels (including the widely used modified 9% chrome alloys), to austenitic stainless steels, to nickel alloys. Packing systems are based on graphite material, but ceramic fiber yarn packing sets are also available for temperatures exceeding 600°C. Materials are either to ASTM/ASME standards or to EN standards, either harmonized or calculated to design conditions. Pressure classes (per ASME standard) are normally ranging from 900# to 1500#, 2500# and 4500#, the last one being manufactured only in the forged body construction.

These valves require, depending on operation conditions, body cavity overpressure relief systems and/or warm up bypass systems, all made available by FLUITEK ORSENIGO VALVES to customer’s demand. The forged body construction allows FLUITEK ORSENIGO VALVES to supply this product with dimensions and pressure classes out of standard, designed to the specific requirements of the customer (temperature, pressure, size of the line) without any dimensional limitation.