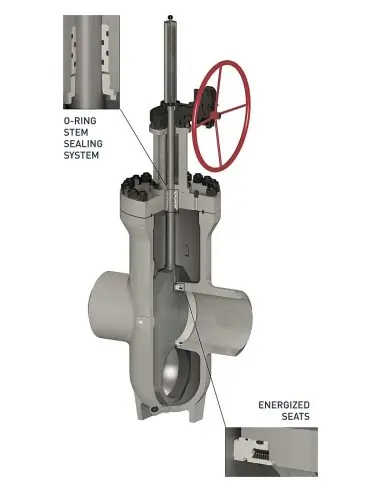

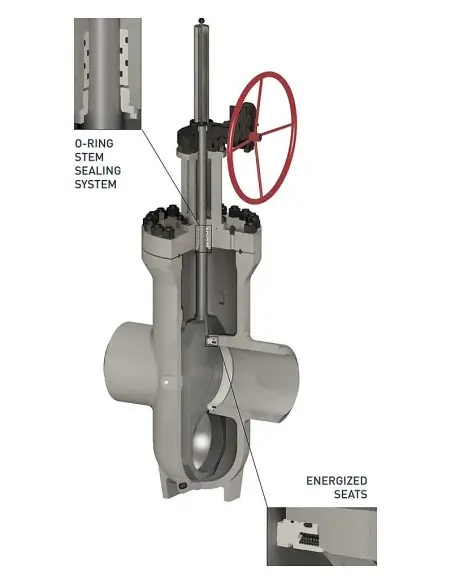

Through conduit gate valves are an alternative to ball valves for transmission pipelines. The choice is very often based on past customer satisfaction, more than any technical consideration. FLUITEK ORSENIGO VALVES through conduit valves feature standard principles of this well known type of product. The disc is of slab type gate, seat rings are floating, energized by means of multiple springs, and the line fluid pressure pushes the upstream ring against the disc, thus assuring the sealing. The system allows the so called “self relieving” effect, i.e. any over-pressure acting in the body cavity is discharged in the line when force caused by the over-pressure on the seats exceeds the force provided by the springs. At the same time, the construction permits the double block and bleed functioning meaning that pressure applied contemporaneously upstream and downstream pushes both seats against the disc and opening the body cavity bleed relieves any pressure and fluid in the body cavity.

Standard construction is based on cast body, disc from plate or forging and all parts, particularly body cavity and disc, are precisely machined to control with high accuracy the parallelism and orthogonality of the parts. Two basic sealing systems are provided: soft seating and metal-to-metal seating. The first for gas and clean liquids service, the second for fluids containing solids or otherwise abrasive components. The soft seated construction is normally provided with secondary sealing system, i.e. with the ability of injecting a highly dense fluid (grease) into the seating area to help sealing mechanism in case of damage of the soft inserts.

A variety of materials are available: carbon steel, low temperature carbon steel, austenitic stainless steel, duplex and superduplex stainless steel and nickel alloys. Compliance with NACE MR-01-75 and NACE MR-01-03 is provided. Soft seated valves are provided with reinforced PTFE or Nylon inserts, depending on specific service and pressure class. Coatings include electroless nickel plating, nickel alloy overlays of seat pockets, tungsten carbide coating for metal-to-metal seated valves.

Standard of reference is API 6D full bore. Flanged and BW ends available. Construction with extension pups is also available, upon customer request. Stem sealing alternatives: o-rings, adjustable packing system, enclosed packing system with Chevron-type rings and lantern ring with grease injection fitting. Very often this type of valve is used in underground service and proper stem extensions are provided. Testing is per standard requirements, or per any supplementary test request by customers.