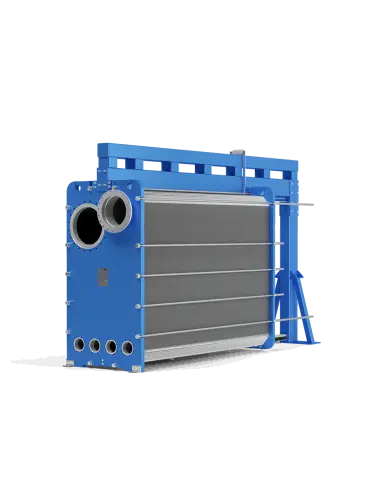

Εξατμιστές Sondex/Danfoss – Απόδοση και Αξιοπιστία στη Βιομηχανία

Οι Εξατμιστές Sondex/Danfoss φέρνουν νέα πνοή στην εξάτμιση υγρών για βιομηχανικές εφαρμογές. Σχεδιασμένοι με προηγμένη τεχνολογία, εξασφαλίζουν υψηλή απόδοση και αντοχή ακόμα και στις πιο απαιτητικές συνθήκες. Η κατασκευή τους προσφέρει σταθερότητα και ασφάλεια σε κάθε στάδιο λειτουργίας, ενώ η συντήρησή τους είναι απλή και γρήγορη.

Χαρακτηριστικά & Οφέλη των Εξατμιστών Sondex/Danfoss

- Υψηλή Απόδοση: Βελτιστοποιημένη μεταφορά θερμότητας και άριστη εξάτμιση για μέγιστη αποτελεσματικότητα.

- Εύκολη Εγκατάσταση: Ο αρθρωτός σχεδιασμός επιτρέπει γρήγορη και ασφαλή ενσωμάτωση στις υπάρχουσες γραμμές παραγωγής.

- Αντοχή στο Χρόνο: Τα υλικά υψηλής ποιότητας εξασφαλίζουν μεγάλη διάρκεια ζωής χωρίς συχνές επισκευές.

- Εξοικονόμηση Ενέργειας: Ελαχιστοποιούν την απώλεια θερμότητας και μειώνουν το κόστος λειτουργίας.

- Ασφαλής Λειτουργία: Πιστοποιημένα προϊόντα με αυστηρό έλεγχο ποιότητας, για πλήρη ασφάλεια της παραγωγής σας.

- Ευέλικτες Εφαρμογές: Ιδανικοί για χρήση σε βιομηχανίες τροφίμων, φαρμάκων, χημικών και σε πολλές άλλες βιομηχανικές διαδικασίες.

Οι Εξατμιστές Sondex/Danfoss είναι σχεδιασμένοι ώστε να απλοποιούν την καθημερινή εργασία, κάνοντας τη διαδικασία εξάτμισης αποτελεσματική και ομαλή. Με τη χρήση τους, κάθε βιομηχανική μονάδα απολαμβάνει καλύτερη απόδοση, χαμηλότερα λειτουργικά έξοδα και λιγότερα προβλήματα συντήρησης.

Επιλέξτε τους Εξατμιστές Sondex/Danfoss και ανακαλύψτε την ιδανική λύση για κάθε βιομηχανική απαίτηση, με αξιοπιστία και τεχνολογική υπεροχή που κάνει τη διαφορά.