Thermodynamic

Thermodynamic

Thermodynamic steam traps are essential components for managing steam systems in various industrial settings. These reliable devices help remove condensate and air from steam lines, ensuring that only dry steam continues through the system. By efficiently separating unwanted moisture, thermodynamic steam traps help equipment run smoothly and safely, protecting valuable machinery from damage caused by water buildup.

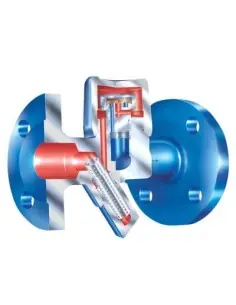

What sets thermodynamic steam traps apart is their simple yet robust design. They use the difference in velocity and pressure between steam and condensate to open and close a disc, effectively controlling the flow. This mechanism allows them to handle high pressure and temperature, making them a popular choice for demanding tasks in factories, power plants, chemical facilities, and refineries.

These steam traps are compact, easy to install, and require minimal maintenance. Their straightforward operation means you can rely on them to work dependably under tough conditions, even when steam demand varies throughout the day. Suitable for both horizontal and vertical installations, they offer flexibility to fit different piping arrangements.

Using thermodynamic steam traps helps save energy and lower costs by preventing steam loss. They also help maintain consistent system performance, which translates to improved productivity and less downtime. For industries that rely on efficient steam management, thermodynamic steam traps are an excellent solution for keeping operations safe, efficient, and cost-effective.