The on-off pipeline valves included in FLUITEK ORSENIGO VALVES lines of production (ball valves, through conduit gate valves) need very often to be installed in lines subject to “pigging” operations, either for lines internal periodical cleaning and/or for checking status of corrosion of the pipeline. In this case the non return valves need to present no obstacle to the passing of the pig.

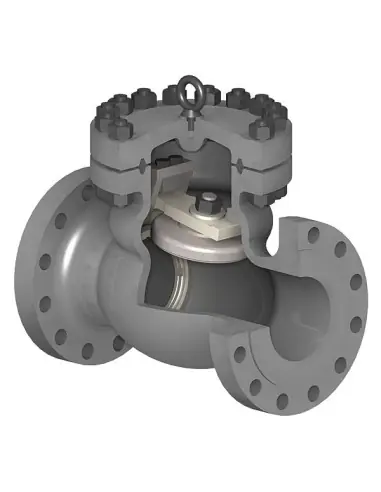

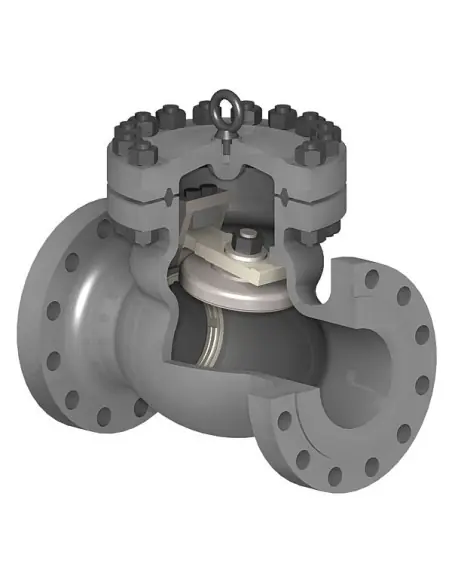

FLUITEK ORSENIGO VALVES has a line of such valves, referred as full opening in API 6D standard. Normal construction is with internal hinge pin, but construction with hinge pin with external insertion is also available. This second construction allows application of additional market requirements, such as position indicator (with or without limit switches), locking systems in the open position, anti-slam external counter weights, rotary anti-slam system (so called “dash pot”).

Materials available are all those used in oil or gas pipelines that include carbon steel, high strength carbon steel, low temperature carbon steel, low alloy steel for extra low temperature environment, austenitic stainless steel. ANSI classes normally available are 150#, 300# and 600#.