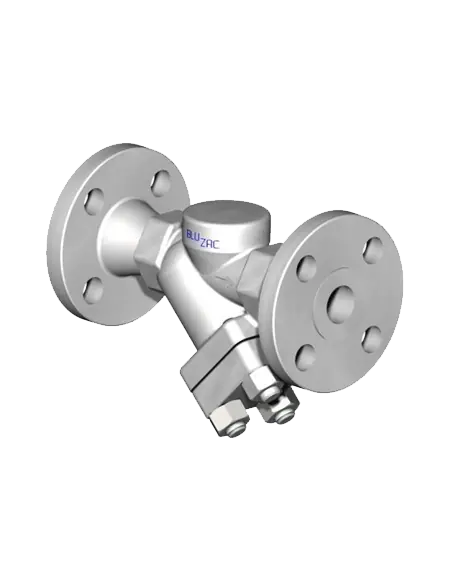

The Y filter is the most common and economical type of filter for permanent fluid or gas applications. Thanks to its compact construction, its light weight and its easy access for rapid cleaning, it is used for many generally standard system applications.

Permanent filter, straight line, suitable for filtering fluids in either the liquid state (water, seawater, petroleum and its derivatives) or the gaseous state (gas, air, chemical products) through a perforated plate filter element placed perpendicular to the direction of flow.

Obtained from a machined forged billet, it is available in all standard materials (Carbon steel WCB Stainless Steel CF8M) and on specific request by the customer in non-standard materials (Duplex S31803, Super Duplex S32750, Inconel, Hastelloy, Cunifer, etc.).

The standard equipment includes a screen suitable for high pressures, which is easy to maintain and replace and capable of filtration of more than 200% of the inlet area.

OPEN AREA RATIO= 100 x Mesh Open Area x Screen Area / Inlet area (The calculations are based on the filtering percentage of the mesh’s surface area only).

| SIZES |

|---|

| from 1/2″ to 2″ |

| CONNECTIONS | ||

|---|---|---|

| Buttweld | BW | ANSI B16.25 |

| Flanged | FLG | ANSI B16.5 |

| Socket Welding |

SW | ANSI B16.11 |

| Screwed | NPT BSP |

ANSI B1.20.1 ANSI BS21 |