Steam Traps - KA 6 | Mankenberg: Reliable Steam Efficiency for Every Industry

Experience seamless steam management with the Steam Traps - KA 6 | Mankenberg, designed specifically for industrial applications that demand dependable performance and maximum energy savings. This advanced steam trap ensures your steam systems operate at peak efficiency, protecting valuable equipment and keeping production running smoothly.

Features & Benefits of Steam Traps - KA 6 | Mankenberg

- Consistent Steam Flow: The KA 6 automatically removes condensate without letting steam escape, ensuring your system maintains optimal pressure and temperature.

- Energy Savings: By preventing steam loss, this trap helps you cut down on unnecessary energy consumption, leading to cost savings and a greener operation.

- Durable Construction: Made with high-quality materials, the KA 6 withstands the toughest industrial environments, offering long-lasting reliability.

- Simple Installation: Its compact design makes it easy to fit into existing pipework, minimizing downtime and installation costs.

- Low Maintenance: The robust self-acting mechanism reduces the need for frequent checks or repairs, so you can focus on your core operations.

- Versatile Applications: Suitable for steam lines, heat exchangers, and process equipment across various industries, from food production to chemical processing.

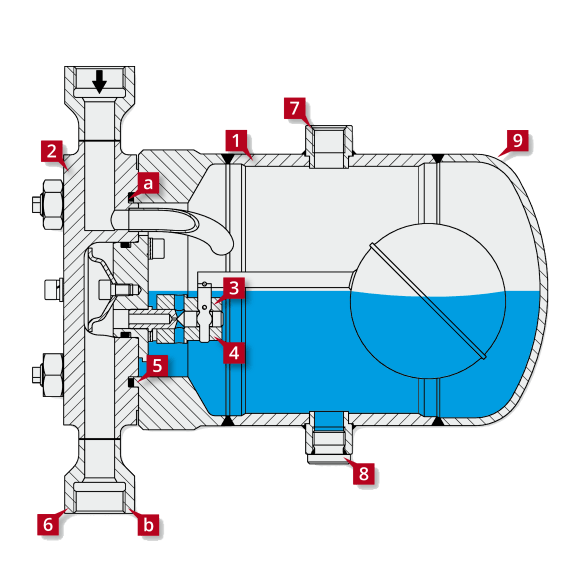

The Steam Traps - KA 6 | Mankenberg stands out for its straightforward operation. It quickly reacts to the presence of condensate, discharging it efficiently while blocking valuable steam. This translates to enhanced equipment protection, as excess water in steam lines can cause corrosion or mechanical damage.

With its user-friendly design, the KA 6 allows maintenance teams to monitor and service the trap easily. Its durable construction ensures minimal interruptions, even in the most demanding settings. The result is smoother process flow, less waste, and better control over your industrial steam use.

Choose the Steam Traps - KA 6 | Mankenberg for a solution that combines reliability, efficiency, and value. Make the smart choice for your facility, and notice the difference in productivity and performance.