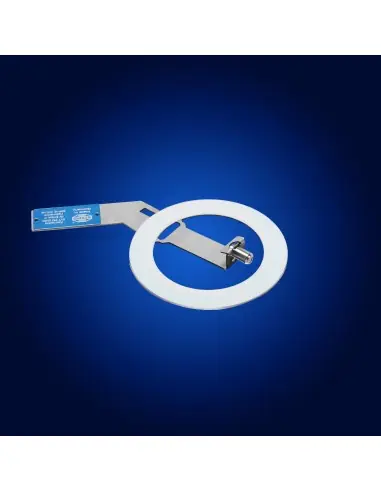

Magnetic burst indicator | Striko: Advanced Safety Meets Simplicity

Enhance your industrial safety standards with the Magnetic burst indicator | Striko, a modern solution designed to provide fast and reliable detection of burst discs. This innovative device is built for precise monitoring, helping you prevent unexpected pressure incidents in your facility. The Striko indicator attaches quickly to your system, delivering crucial information the moment a pressure relief event occurs.

Features and Benefits of Magnetic burst indicator | Striko

- Instant Detection: Know the exact moment your burst disc reacts, thanks to the magnetic sensor technology. This ensures that any sudden pressure release is noticed immediately, reducing the risk of unnoticed system failures.

- Effortless Integration: Designed for industrial use, the indicator fits seamlessly with common safety systems. Installation is straightforward, with no need for complex tools or wiring, making it an easy upgrade for both new and existing setups.

- Highly Reliable Alerts: The magnetic sensor provides clear and unmistakable signals. Once the burst disc activates, a strong indicator signal lets your team respond quickly, minimizing downtime and potential hazards.

- Durable Construction: Built from robust materials, the Magnetic burst indicator | Striko withstands tough industrial environments, ensuring consistent performance over time.

- Minimal Maintenance: The smart design means you spend less time on upkeep. With no moving parts, the indicator remains accurate and dependable through thousands of operating cycles.

- Easy Monitoring: The device’s visual signals are simple to understand, even for staff without technical backgrounds. Anyone on your team can check system status at a glance.

The Magnetic burst indicator | Striko transforms how you manage pressure safety. By providing immediate feedback, it allows quick response to potential issues, protecting both equipment and personnel. Whether you are upgrading your plant’s existing safety measures or outfitting a new system, this indicator delivers peace of mind with its accuracy and simplicity.

Choose the Magnetic burst indicator | Striko for a practical and effective way to improve industrial safety. With straightforward installation, user-friendly operation, and robust design, it stands out as a reliable choice for any facility focused on safe and efficient operations.