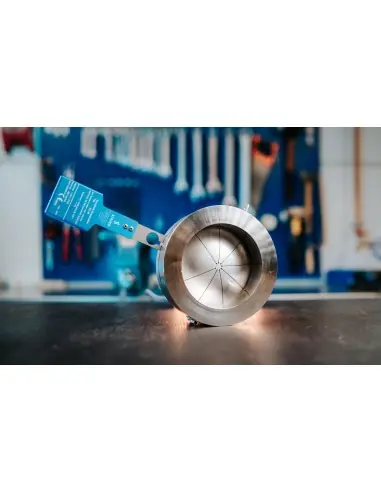

Forward Acting Metal Rupture Disc | Striko: Reliable Safety for Industrial Systems

When it comes to protecting industrial equipment and processes, the Forward Acting Metal Rupture Disc | Striko stands out as a dependable safety solution. Engineered for precise performance, this rupture disc is designed to respond quickly when pressure in your system reaches unsafe levels, offering peace of mind and protecting valuable assets from unexpected damage.

Features & Benefits of Forward Acting Metal Rupture Disc | Striko

- Instant Pressure Relief: The rupture disc opens immediately when your system’s pressure exceeds the safe limit, preventing equipment failure or explosion.

- High Accuracy: Manufactured with tight tolerances, ensuring the disc activates precisely at the required pressure, so you get reliable, predictable performance every time.

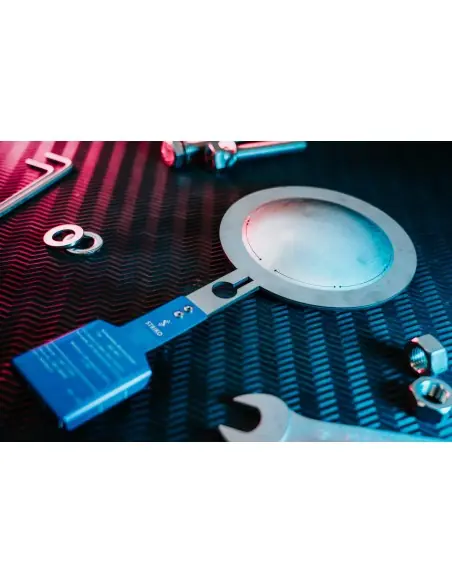

- Low Maintenance: With no moving parts, this disc requires minimal upkeep, saving time and reducing operational costs.

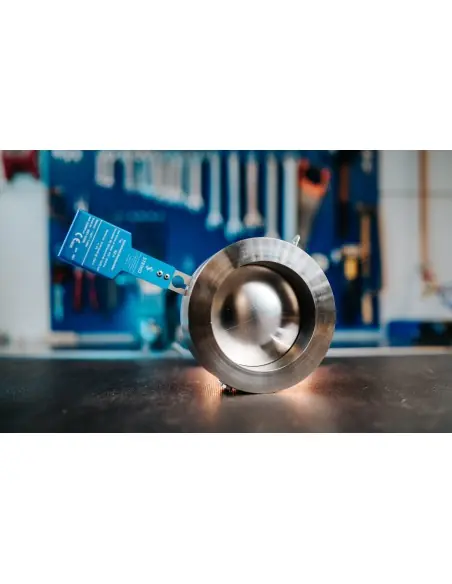

- Durable Construction: Made from robust metal alloys, it withstands harsh industrial environments and resists corrosion and wear.

- Easy Installation: The user-friendly design allows for quick and straightforward fitting, minimizing downtime and boosting productivity.

- Leak-Tight Seal: The solid metal construction provides a dependable seal, ensuring that your system won’t leak under normal operating conditions.

- Versatile Application: Suitable for a wide range of industries, from chemical and petrochemical to food processing and energy.

Forward Acting Metal Rupture Disc | Striko is built to act as a critical last line of defense for your industrial setups. When pressure surges threaten safety, the disc bursts along a precisely manufactured score line, releasing pressure and protecting both equipment and personnel. There’s no need for skilled personnel to operate it once installed, and it works silently in the background without interfering with your process.

Designed for universal compatibility, this rupture disc fits into standard holders, making upgrades or maintenance hassle-free. Its streamlined design reduces the risk of product buildup or contamination, keeping production clean and efficient. The metal construction is chosen for longevity, so you don’t have to worry about frequent replacements or failures.

By choosing Forward Acting Metal Rupture Disc | Striko, you equip your facility with a trusted safety measure. It responds instantly to pressure emergencies, ensuring downtime is minimized and catastrophic failures are prevented. For any plant where pressure control is critical, this rupture disc is an essential component for safety and operational reliability.