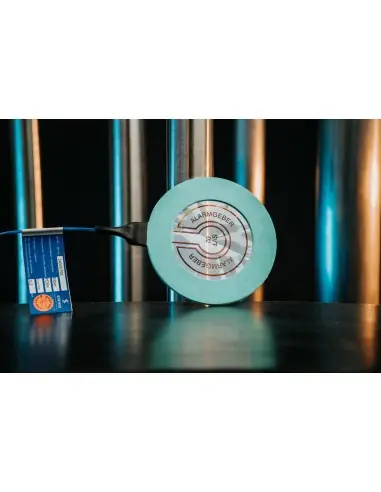

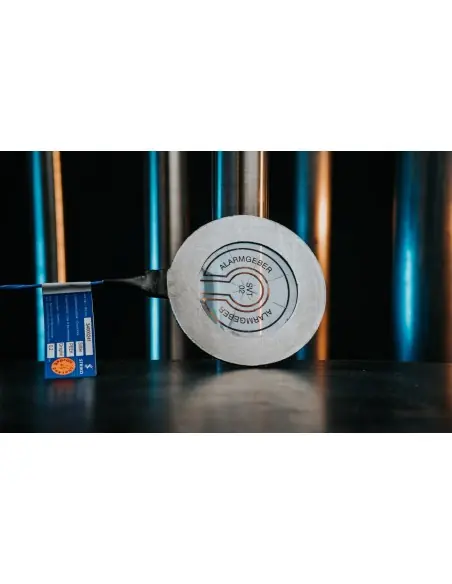

Burst Indicator Type SVT 02 | Striko: Precision Safety for Industrial Reliability

Maximize the safety and efficiency of your industrial processes with the state-of-the-art Burst Indicator Type SVT 02 | Striko. This essential device provides instant notification when pressure relief systems activate, making it a reliable tool for maintaining operational integrity and protecting your equipment. Designed for robust industrial environments, the Burst Indicator SVT 02 delivers accurate detection and immediate feedback, supporting safe and uninterrupted workflows.

Features and Benefits of Burst Indicator Type SVT 02 | Striko

- Instant Notification: Receive clear and immediate alerts if a rupture disc bursts, allowing fast response and reducing unplanned downtime.

- Simple Integration: The device is quick to install and compatible with a wide range of pressure relief systems, minimizing setup time and effort.

- Robust Build: Built from high-quality, durable materials, the SVT 02 withstands harsh conditions and continuous industrial use, ensuring long-lasting performance.

- Clear Signals: The indicator offers unmistakable visual or electronic signals, making the status of your safety systems easy to monitor from a distance.

- Maintenance Friendly: Requires minimal upkeep, helping you keep maintenance schedules simple and costs low.

- Enhanced Safety: By quickly indicating a breach, the SVT 02 helps prevent further equipment damage and protects your personnel, ensuring a safer workspace.

- Versatile Application: Suitable for various industries, including chemical, pharmaceutical, food manufacturing, and energy sectors.

The Burst Indicator Type SVT 02 | Striko translates advanced safety technology into easy-to-use protection for any industrial setting. Its reliable performance means your pressure relief systems are always under watch, so you can focus on what matters most—smooth and safe operation. Say goodbye to uncertainty and equip your facility with a solution that delivers confidence and control every day.