Pressure reducing valve - Direct Acting for steam - REH20 | Miyawaki: The Intelligent Solution for Safe and Efficient Steam Control

Experience new levels of performance and reliability with the Pressure reducing valve - Direct Acting for steam - REH20 | Miyawaki. Perfect for industrial environments, this valve ensures precise steam pressure management, helping protect equipment, optimize energy use, and maintain a steady operation. Designed with convenience and safety in mind, it’s the ideal choice for efficient steam systems across various industries.

Features & Benefits of the Pressure reducing valve - Direct Acting for steam - REH20 | Miyawaki

- Direct Acting Mechanism: Unlike complex multi-part systems, this valve offers direct action for rapid, responsive pressure control. This keeps your steam flow steady and reliable, minimizing sudden surges or drops.

- Robust Construction: Made from high-quality, corrosion-resistant materials, the REH20 ensures longevity and safe operation, even under demanding conditions.

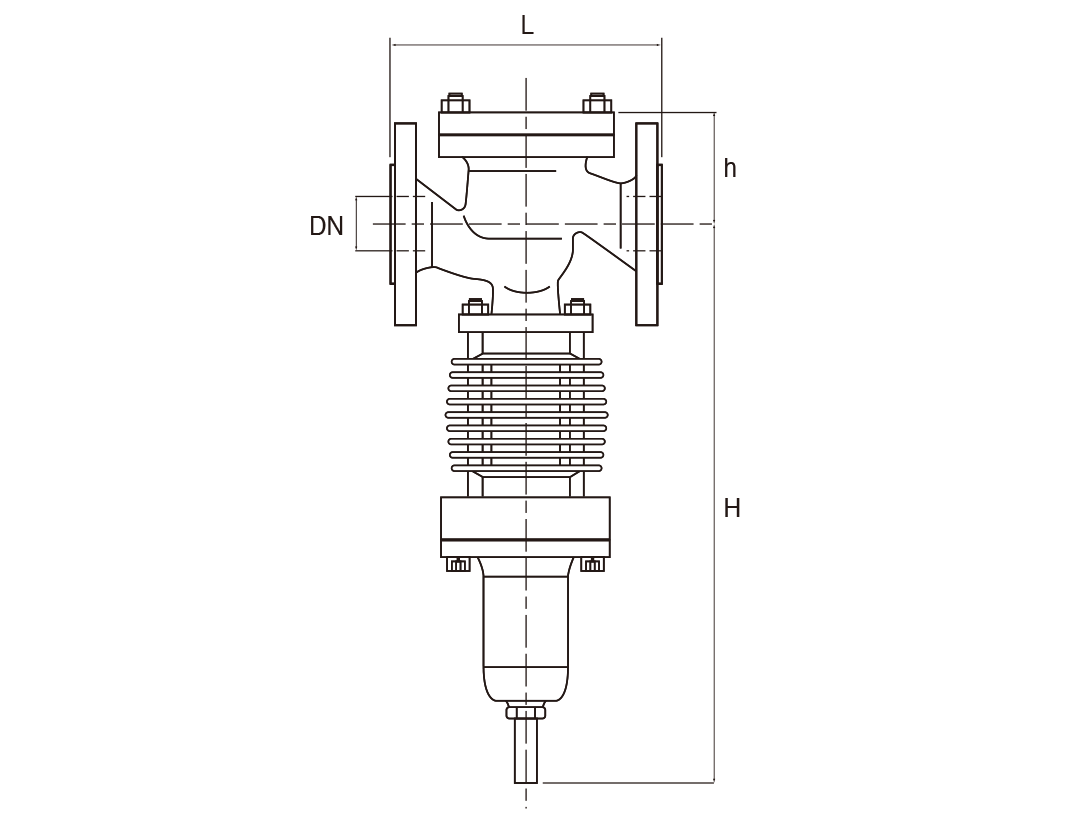

- Easy Installation & Maintenance: Its compact design and simple layout make installation straightforward. Maintenance is just as easy, reducing downtime and supporting smooth operations.

- Accurate Pressure Adjustment: The valve allows precise steam pressure control, protecting sensitive machinery and helping you meet exact requirements for various processes.

- Energy Efficiency: By maintaining ideal pressure, the REH20 optimizes steam consumption, cutting down on energy waste and lowering operational costs.

- Reliable Performance: Miyawaki’s engineering guarantees consistent, dependable operation vital for industrial safety and productivity.

With the Pressure reducing valve - Direct Acting for steam - REH20 | Miyawaki, you gain an advanced yet user-friendly tool for your steam system. The valve is meticulously engineered to offer stable pressure reduction, protecting delicate equipment and preventing costly system failures. Its versatility means it’s suitable for applications ranging from food production to textile manufacturing.

Choosing the REH20 means you benefit from hassle-free operation and improved workplace safety. By simplifying the job of pressure control, you minimize operational mistakes and boost peace of mind. Built to last with minimal service needs, this valve represents a smart investment in operational reliability and efficiency. Upgrade to the REH20 and notice the difference in your steam management right away.