Optimize Your Steam Systems: Pressure Reducing Valve - Direct Acting for Steam - RE20 | Miyawaki

Maximize efficiency and reliability in your industrial steam system with the Pressure Reducing Valve - Direct Acting for steam - RE20 | Miyawaki. Designed for heavy-duty use, the RE20 ensures your steam processes run smoothly by automatically controlling and reducing the pressure to safe and stable levels.

Features & Benefits of the Pressure Reducing Valve - Direct Acting for Steam - RE20 | Miyawaki

- Consistent Pressure Control: The RE20 maintains a steady outlet pressure even when your steam supply fluctuates. This keeps your equipment protected and your operation running without interruptions.

- Fast and Direct Response: The direct acting design reacts instantly to pressure changes, offering accurate and reliable adjustment as soon as it’s needed.

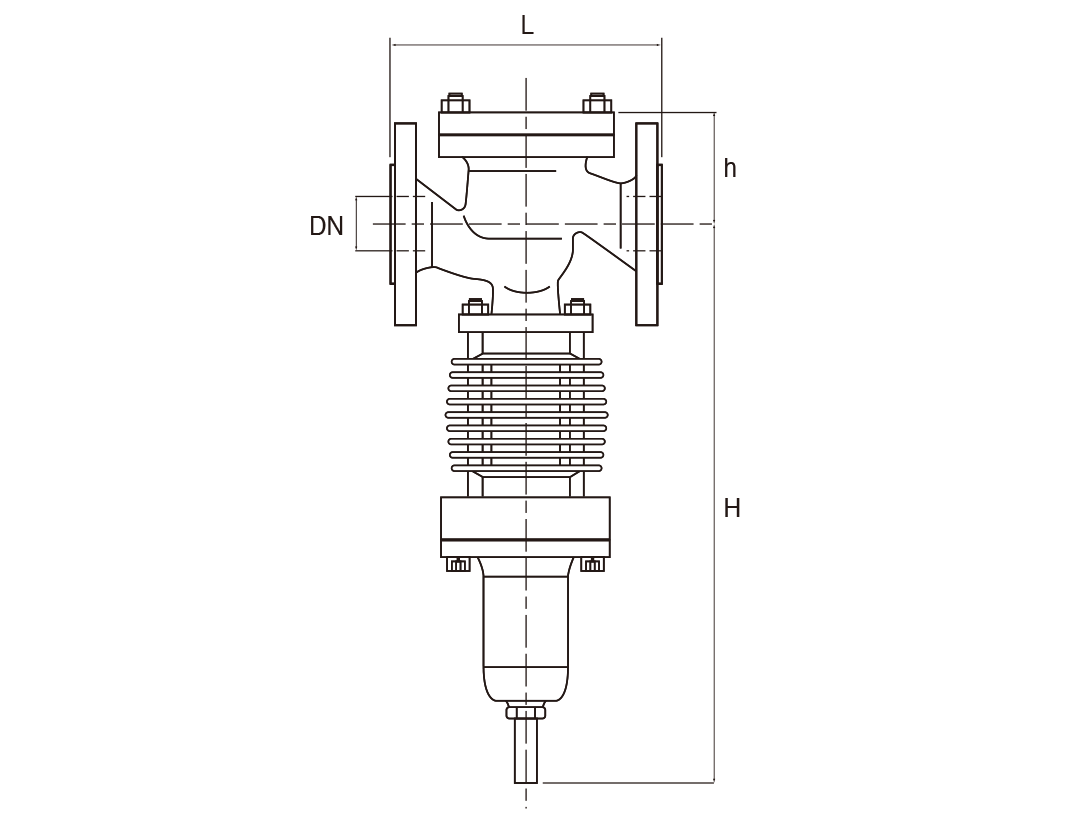

- Simple Installation: With a compact and robust build, the RE20 can be easily installed in tight spaces, making it ideal for busy industrial environments.

- Low Maintenance: The valve’s durable construction means fewer breakdowns and longer service intervals, helping reduce downtime and costs.

- Energy Savings: By precisely regulating steam pressure, the RE20 prevents waste, helping lower energy expenses and improve overall performance.

- Enhanced Safety: The valve safeguards equipment from pressure surges, reducing the risk of leaks or damage and supporting a safer workplace.

- Versatile Application: Suitable for a wide range of industrial steam applications, the RE20 adapts easily to both new and existing systems.

The Pressure Reducing Valve - Direct Acting for steam - RE20 | Miyawaki is an essential component for anyone seeking cost-effective, secure, and stable steam operations. Its innovative design ensures precise regulation while keeping maintenance simple. From manufacturing lines to heating systems, this valve delivers reliable pressure control, helping protect your investment, boost efficiency, and ensure long-term performance.

Upgrade your steam system today with the RE20 and experience the difference in operational stability and energy savings.