Plate Ηeat Εxchangers

Plate Ηeat Εxchangers

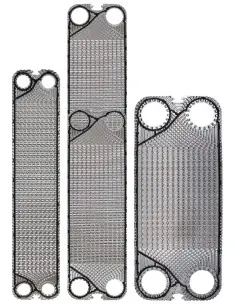

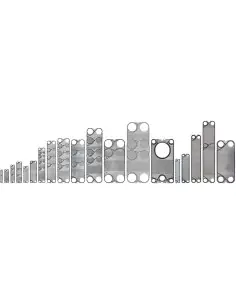

Plate heat exchangers are essential tools in many industries for controlling temperatures during various processes. These devices use a series of thin, corrugated metal plates to transfer heat between two fluids without mixing them. This design makes them highly efficient, allowing businesses to save on both energy and space. Industries such as food and beverage, chemical production, HVAC, and power generation all rely on plate heat exchangers to maintain precise temperatures and keep operations running smoothly.

One of the main advantages of plate heat exchangers is their flexibility. They can be easily adjusted or expanded to handle different flow rates or temperatures, making them a practical solution for growing businesses. Their compact design means they take up less space compared to other types of heat exchangers, like shell-and-tube models. Cleaning and maintenance are straightforward since the plates can be separated and serviced individually.

Using plate heat exchangers helps protect equipment from overheating, improves energy efficiency, and reduces operational costs. They are built to handle demanding industrial environments and can process a wide range of liquids, including those with varying levels of viscosity. If your business needs a reliable way to manage heat transfer, plate heat exchangers offer a smart, economical, and long-lasting solution.

Active filters

Plate Ηeat Εxchangers

Plate Heat Exchangers Certified by AHRI | SonFlow

Plate Ηeat Εxchangers

Brazed Plate Heat Exchangers | SonFlow

Plate Ηeat Εxchangers

Free Flow Plate Heat Exchanger | SonFlow

Plate Ηeat Εxchangers