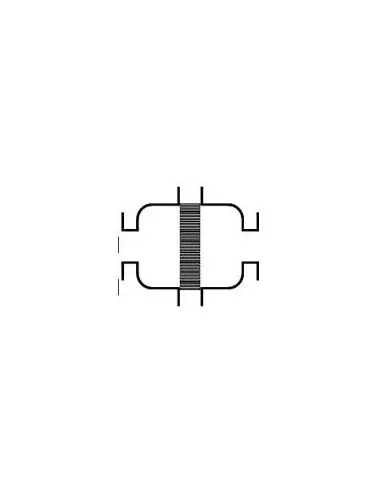

KITO® CFA-Det4-IIA-…/…-…

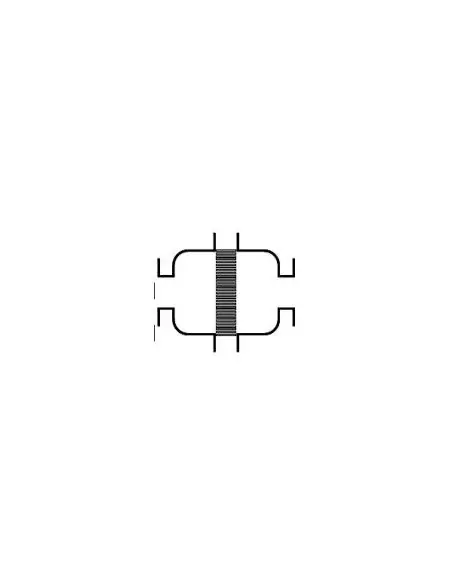

KITO® CFA-Det4-IIA-…/…-…-T (-TT)

- For installation into pipes to the protection of vessels and components against stable detonation of flammable liquids and gases.

- Tested and approved as detonation flame arrester type 4.

- Approved for all substances of explosion groups IIA1 to IIA with a maximum experi-mental safe gap (MESG) > 0.9 mm.

- Bi-directionally working in pipes, whereby an operating pressure of 2.5 bar abs. up to NG 300, pmax = 2.0 bar abs. from NG 400 and an operating temperature of 60 °C must not be exceeded.

- The installation of the detonation flame arrester into horizontal and vertical pipes is permissible.

- Provided with one or two temperature sensors (PT 100) the armature is certified against short time burning from one or both sides.

- If only one thermal sensor is attached, it must be installed into that part of the body from which a fire is expected.

- Equipped with two head pipes plugs for draining condensate.