KITO® EFA-Def0-IIC-…/…-1.2

KITO® EFA-Def0-IIC-…/…-1.2-T (-TT)

- For installation into pipes to the protection of vessels and components against deflagration of flammable liquids and gases.

- Approved for all substances of explosion groups IIA1 to IIC with a maximum experimental safe gap (MESG) < 0.5 mm.

- Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60 °C must not be exceeded.

- The distance between a potential ignition source and the flame arrester must not exceed 30 times the inner pipe diameter.

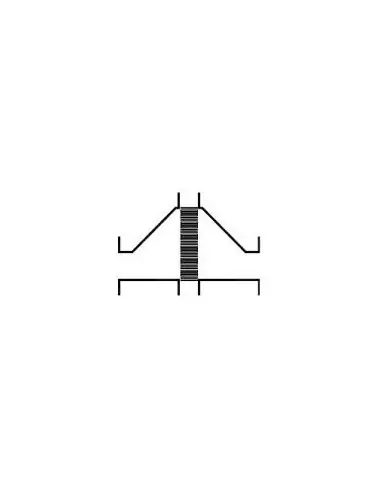

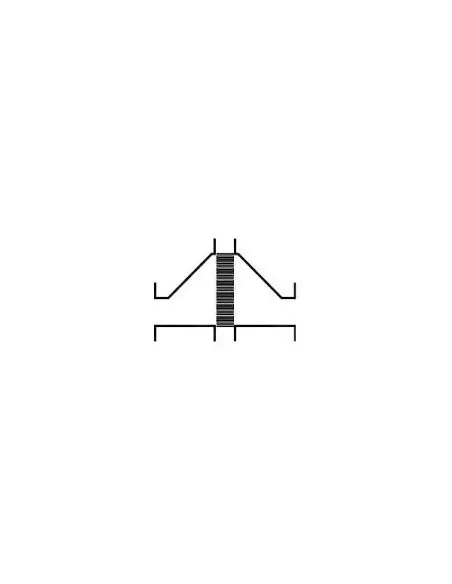

- The installation of the Deflagration flame arrester into horizontal and vertical pipes is permissible.

- When equipped with one or two temperature sensors, the devices are protected under atmospheric conditions against a short time burning by a burning time tBT = 1.0 min.

- If only one temperature sensor, then it is to be placed on the device side where a burning could be expected.