Dog Bone Expansion Joints | Macoga – Reliable Solutions for Industrial Piping

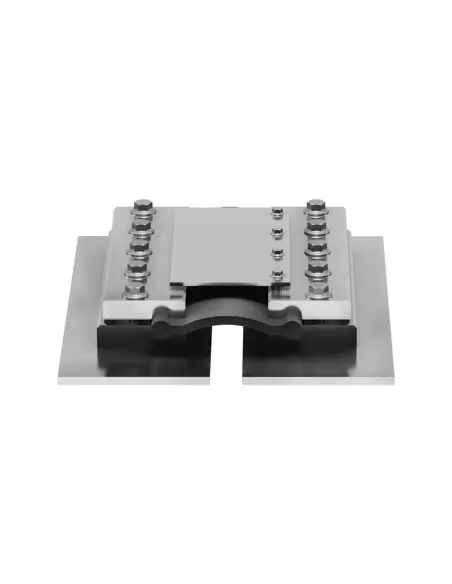

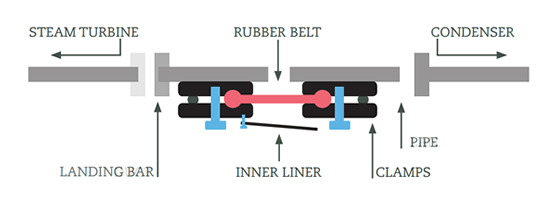

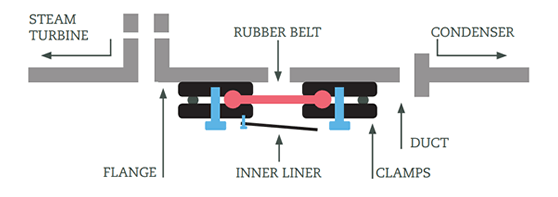

Discover the innovative Dog Bone Expansion Joints | Macoga, designed to tackle challenging movements in piping systems across various industries. Built for safety and efficiency, these expansion joints ensure seamless fluid flow while protecting pipes from strain and damage.

Outstanding Features & Benefits of Dog Bone Expansion Joints | Macoga

- Superior Flexibility: Dog Bone Expansion Joints are engineered to handle large lateral and angular movements. Their unique shape allows pipes to move without causing cracks or leaks, maintaining integrity even under tough conditions.

- Durable Construction: Made from top-grade materials, these joints resist wear and corrosion. This means less frequent replacements, reducing maintenance costs and downtime for your operations.

- Enhanced Safety: By absorbing vibration and thermal expansion, these joints minimize the risk of unexpected pipe failures. Protecting employees and equipment becomes easier and more reliable.

- Easy Integration: Lightweight and compact, Dog Bone Expansion Joints can be fitted into existing piping systems with minimal disruption. Their design suits both new installations and upgrades.

- Cost-Effective Performance: Reducing the stress on pipes leads to longer system life and fewer repairs. This smart choice means better long-term savings for your facility.

Every Dog Bone Expansion Joint | Macoga meets strict quality standards, ensuring top performance in demanding environments like power plants, oil refineries, and chemical facilities. Whether dealing with high pressures or fluctuating temperatures, these expansion joints adapt to your system’s needs.

Enjoy peace of mind with a solution that’s proven to work under pressure. The Dog Bone Expansion Joints | Macoga are trusted by industry professionals worldwide for their reliability and smart engineering. Choose Macoga for a smoother, safer, and more efficient piping system.

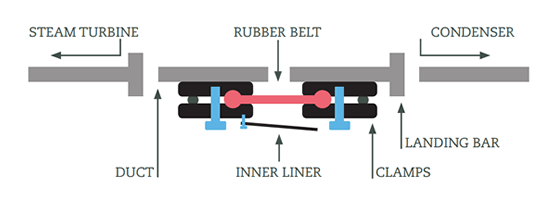

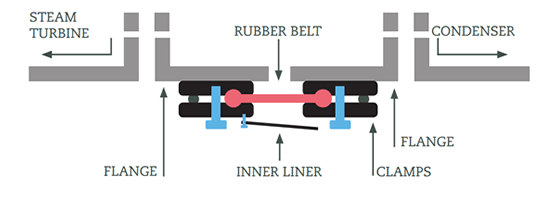

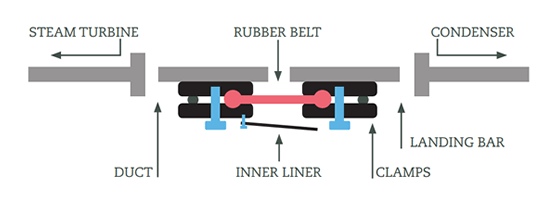

Description

CERTIFICATES

MACOGA holds numerous industry approvals, including:

Ministry of Defense and NATO Member Countries